From powering precision components in Huawei’s 5G infrastructure to enabling cutting-edge battery systems for BYD’s electric vehicles, our ceramic rods meet the exacting standards of global industry leaders. Chosen by Apple for micro-mechanical assemblies and specified in Meta’s data center cooling solutions, we deliver the dimensional stability and material integrity required for mission-critical applications.

We will get back to you within 12 hours.

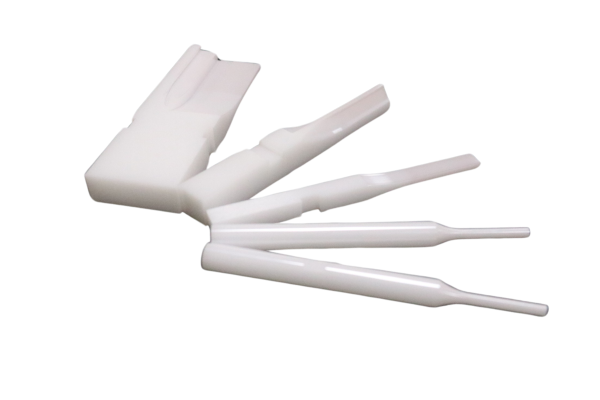

At ESHINO, we don’t just manufacture ceramic rods—we redefine performance. With over a decade of mastery in advanced ceramic machining, our rods are trusted globally for their unmatched strength, extreme hardness, and superior toughness. Here’s why industry leaders choose us:

ISO9001-Certified Precision: Every rod undergoes several quality checks to guarantee perfection.

Global Compliance: Fully compliant with US and EU standards—seamless for international projects.

Cutting-Edge Solutions: Proprietary machining technology delivers tolerances within ±0.002mm.

Our rods aren’t just components—they’re performance multipliers. Whether your application demands ultra-high thermal resistance, electrical insulation, or wear-proof durability, we engineer solutions that outlast and outperform.

Contact us now for a free technical consultation + sample quote.

Precision ceramic rods are utilized in CNC machines as guide rails, providing exceptional stiffness, low thermal expansion, and resistance to wear. These properties ensure high-precision movements, enhancing machining accuracy and extending equipment lifespan.

In high-temperature furnaces and kilns, ceramic rods serve as structural supports due to their outstanding thermal shock resistance and stability. They maintain structural integrity under extreme conditions, ensuring consistent performance in demanding environments.

Technical ceramic rods are employed as precision shafts in medical imaging, optical equipment and other ways. Their dimensional stability and resistance to thermal expansion ensure accurate and reliable operation, meeting stringent medical industry standards.

ESHINO is a precision advanced ceramic rods manufacturer in China, main materials are Zirconia Ceramics (ZrO2), Alumina Ceramic (Al2O3), Silicon Nitride Ceramics (Si3N4) and Silicon Carbide Ceramics (SiC). Equipped with full set of advanced machines to ensure production capacity and quality. Each process is operated strictly in accordance with SOP.

Quality always comes first for us. Everyone in ESHINO is quality inspector. Our value is to solve problems for clients but not create them.

We will get back to you within 12 hours.