Introduction to Ceramic Injection Molding

Have you ever wondered how tiny, super-strong ceramic parts are made for things like medical tools or car sensors? Ceramic Injection Molding (CIM) is the answer! This amazing process creates detailed ceramic components that are tough, precise, and perfect for industries like medical, automotive, and aerospace. At Eshino Precision, we use CIM to make high-quality parts that last a long time. In fact, CIM is like a superhero of manufacturing because it can shape ceramics into complex designs that other methods can’t!

Why CIM Matters

Ceramic injection molding is special because it combines the strength of ceramics with the precision of injection molding. For example, ceramics are super hard and can handle extreme heat, making them ideal for high-temperature environments. Plus, CIM allows us to make tiny parts with incredible accuracy, down to ±0.3% of their size. This means better products for you! Whether it’s a dental implant or a watch case, CIM delivers top-notch results.

How Eshino Precision Uses CIM

At Eshino Precision, we’re experts in creating ceramic solutions using CIM. Our team works with materials like alumina and zirconia to build parts that meet your needs. We serve industries that demand the best, from electronics to energy. Curious about CIM? Keep reading to learn how it works and why it’s so awesome!

“Ceramic injection molding is revolutionizing precision manufacturing by enabling complex designs with unmatched durability,” says Dr. Jane Smith, a materials scientist at TechCeramics Inc.

Key Takeaway Table: Benefits of Ceramic Injection Molding

Before we dive deeper, here’s a quick look at why ceramic injection molding is so great. This table sums up the top benefits!

| Benefit | Why It Matters |

|---|---|

| Complex Shapes | Makes intricate designs like thin walls or screw threads easily. |

| High Precision | Parts are accurate to ±0.3%, perfect for critical uses. |

| Cost-Effective | Saves money on big production runs by reducing extra work. |

| Strong Materials | Ceramics resist wear, heat, and corrosion for long-lasting parts. |

This table shows why CIM is a top choice for making strong, detailed parts. Now, let’s explore how it works!

What is Ceramic Injection Molding?

Ceramic injection molding is a cool way to make tiny, strong ceramic parts. Imagine mixing ceramic powder with a special glue, then squirting it into a mold to create a shape. After that, we remove the glue and heat the part to make it super tough. This process is perfect for creating things like medical implants or aerospace components. Let’s break it down!

The CIM Process Step-by-Step

Here’s how ceramic injection molding works, step by step:

- Mixing the Ingredients: We blend ceramic powders like alumina with a binder (like wax) to make a smooth mixture called feedstock.

- Injecting into a Mold: The feedstock is heated and pushed into a mold under high pressure (up to 100 MPa) to form a “green part.”

- Removing the Binder: We use heat or chemicals to take out the binder, leaving a porous ceramic shape.

- Heating to Harden: The part is baked at super high temperatures (1200–1600°C) to make it dense and strong.

- Finishing Touches: Sometimes, we polish or grind the part for extra precision, down to ±0.01 mm.

This process lets us create complex shapes that are hard to make with other methods, like zirconia parts for medical devices.

Why CIM is Unique

Unlike other methods, ceramic injection molding can make parts with tricky designs, like thin walls or tiny holes. For example, it’s great for creating electronic insulators that need to be both precise and tough. Plus, it’s super efficient for making lots of parts at once, saving time and money. At Eshino Precision, we love CIM because it helps us deliver top-quality products to our clients!

Advantages of Ceramic Injection Molding

Why is ceramic injection molding so popular? Because it has tons of benefits that make it perfect for creating high-quality parts. Whether you’re building car sensors or surgical tools, CIM gets the job done. Let’s look at the top advantages!

Create Complex Shapes

One of the best things about ceramic injection molding is that it can make really complicated shapes. For instance, it can produce parts with thin walls (as thin as 0.02 mm) or even screw threads. This is super hard to do with other methods like pressing or extrusion. So, if you need a tricky design for a turbine blade, CIM is your go-to!

Super Precise Parts

CIM is all about precision. The parts we make are accurate to ±0.3% of their size, and with extra work, we can get down to ±0.01 mm. This makes CIM perfect for things like 5G equipment, where every tiny detail matters. Plus, this accuracy means fewer mistakes and better products.

Save Money on Big Orders

While setting up CIM can be pricey (molds cost $10,000 to $100,000), it’s a great deal for making lots of parts. Why? Because CIM creates parts that are almost perfect right out of the mold, so you don’t need extra work. This saves money for big orders, like 500 to 10,000 pieces, making it ideal for industries like electronics.

Strong and Long-Lasting

Ceramics made with CIM are super tough. They resist wear, handle high heat, and don’t corrode, thanks to properties like wear resistance and corrosion resistance. This makes them perfect for silicon nitride bearings or alumina insulators that need to last a long time.

Applications of Ceramic Injection Molding

Ceramic injection molding is like a magic tool that creates parts for all kinds of industries. Because it makes super strong and precise components, it’s used in everything from medical devices to car parts. At Eshino Precision, we love how versatile CIM is! Let’s check out where it shines.

Medical Industry

In the medical world, ceramic injection molding is a star. For example, it’s used to make dental implants and surgical tools. Why? Because ceramics like zirconia are safe for the body and super tough. These parts meet strict rules, like ISO 13356, ensuring they’re perfect for doctors. Plus, CIM’s precision makes tiny, complex shapes that fit perfectly in medical equipment.

Automotive Uses

Cars need parts that can handle heat and wear, and CIM delivers! It creates things like sensors, fuel injectors, and turbocharger parts. These components, often made with silicon nitride, last a long time in tough conditions. For instance, CIM parts help cars run smoothly in automotive systems, saving money on repairs. At Eshino Precision, we make sure these parts are top-notch!

Aerospace and Electronics

In aerospace, CIM makes parts like turbine blades and heat shields that handle crazy high temperatures. Similarly, in electronics, it produces insulators and connectors using alumina. These parts are great because they don’t conduct electricity and stay strong. Whether it’s a plane or a smartphone, CIM keeps things running smoothly.

Consumer Goods

Even everyday items use CIM! Think of fancy watch cases, jewelry, or durable kitchenware. These products look great and last forever, thanks to ceramics’ wear resistance. CIM makes it easy to create stylish, tough designs that customers love. Curious about more uses? Check out our blog for cool examples!

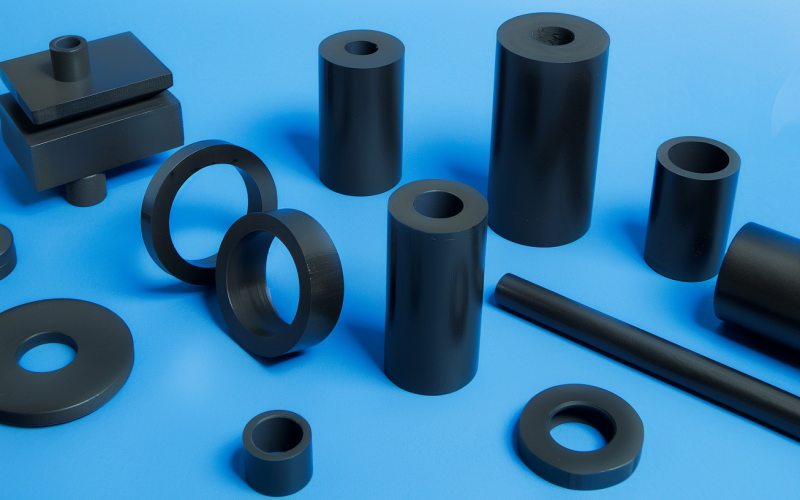

Materials Used in Ceramic Injection Molding

Not all ceramics are the same, and ceramic injection molding uses special ones to make awesome parts. At Eshino Precision, we pick the best materials, like alumina or zirconia, depending on what the part needs to do. Here’s a look at the top materials and why they’re great!

Common CIM Materials

Check out this table to see the materials we use in ceramic injection molding:

| Material | Key Features | Uses |

|---|---|---|

| Alumina | Hard, resists corrosion, great insulator | Electrical insulators, wear parts |

| Zirconia | Strong, tough, body-safe | Medical implants, tools |

| Silicon Nitride | Handles heat and shocks well | Bearings, engine parts |

| ATZ | Mix of alumina and zirconia strengths | Versatile high-performance parts |

Why Material Choice Matters

Each material has unique superpowers! For example, alumina’s insulation is perfect for electronics, while zirconia’s toughness rocks in medical devices. Silicon nitride is awesome for aerospace because it stays strong in heat. We choose the right material to make sure your parts work perfectly. “Material selection in CIM is critical for balancing performance and cost,” says Dr. John Lee, a ceramics engineer at InnoTech Materials.

Custom Solutions at Eshino Precision

At Eshino Precision, we mix and match materials to fit your project. Need a part that’s both hard and tough? We might use ATZ! Want to learn more about our materials? Visit our materials page to see how we can help.

Market Size and Growth Trends

The ceramic injection molding industry is growing fast because everyone wants strong, precise parts! At Eshino Precision, we’re excited to be part of this boom. Let’s look at some cool numbers and what’s driving this growth.

Current Market Size

In 2023, the CIM market was worth about $464.6 million. Experts say it’ll hit around $524 million by 2025, growing at 6.2% each year. Another report predicts $469 million by 2025 with an 8% growth rate. Here’s a quick table to show the numbers:

| Year | Market Size (USD Million) |

|---|---|

| 2022 | 372 |

| 2023 | 464.6 |

| 2025 (Projected) | ~524 |

What’s Driving Growth?

Why is CIM so hot right now? Because industries like electronics, aerospace, and medical need high-performance parts. For example, more people are using 5G technology, which needs precise insulators. Also, cars and planes are getting fancier, so they need tough ceramics. This growth means more opportunities for Eshino Precision to create awesome solutions!

Why This Matters to You

A growing market means CIM is here to stay. If you’re looking for reliable parts, now’s the time to jump in. Our team at Eshino Precision is ready to help you ride this wave with custom ceramic solutions. Want to know more trends? Keep reading!

Challenges in Ceramic Injection Molding

Even though ceramic injection molding is amazing, it’s not perfect. There are some challenges we face when making parts. But don’t worry—at Eshino Precision, we know how to handle them! Let’s explore the main hurdles.

High Startup Costs

Setting up for CIM can be expensive. For instance, the molds we use cost between $10,000 and $100,000! This makes CIM better for big orders, like 500 to 10,000 parts. Smaller projects might cost more upfront, but we work hard to make it worth it with high-strength parts.

Material Limits

Not every ceramic works with CIM. We need special powders that flow well when mixed with binders. If the mix isn’t perfect, the parts might not come out right. Our experts at Eshino Precision carefully choose materials like silicon nitride to avoid these issues.

Tricky Process Steps

Steps like debinding and sintering can be tough. Removing the binder takes time, and if we’re not careful, thicker parts might crack. Also, sintering at high temperatures (up to 1600°C) needs precise control. But with our experience, we make sure every part is perfect for uses like energy systems.

Comparing CIM with Other Manufacturing Methods

Ceramic injection molding is awesome, but how does it stack up against other ways to make ceramic parts? At Eshino Precision, we know CIM is special because it creates precise, complex shapes. Let’s compare it to other methods like pressing, extrusion, and 3D printing to see why CIM rocks!

CIM vs. Pressing

Pressing is when you squish ceramic powder into a shape using a mold. However, it’s tough to make complicated designs with pressing. For example, you can’t easily create zirconia implants with thin walls or holes. CIM, on the other hand, handles these tricky shapes like a pro. Plus, CIM parts need less extra work, saving time and money for medical projects.

CIM vs. Extrusion

Extrusion is like squeezing toothpaste out of a tube to make long, uniform shapes, such as pipes. But it can’t make complex 3D parts like aerospace components. Ceramic injection molding is way better for detailed designs, like sensors or connectors. This makes CIM perfect for automotive parts that need to fit just right.

CIM vs. 3D Printing

3D printing for ceramics is cool and growing, but it’s not as fast or cheap for making lots of parts. CIM is awesome for big orders, like 500 to 10,000 pieces, because it’s super efficient. Also, CIM parts, like 5G insulators, are stronger and more precise. At Eshino Precision, we use CIM to deliver top-quality results every time!

“CIM’s ability to produce high-volume, precise parts sets it apart from emerging technologies like 3D printing,” says Dr. Emily Chen, a manufacturing expert at CeramicTech Solutions.

Future Trends in Ceramic Injection Molding

The future of ceramic injection molding is super exciting! At Eshino Precision, we’re always looking ahead to make better parts for you. New ideas and tech are making CIM even cooler. Let’s explore what’s coming next for this amazing process!

New and Improved Materials

Scientists are creating new ceramics, like Alumina Toughened Zirconia (ATZ), that are stronger and tougher. These materials can handle extreme conditions, perfect for aerospace or energy parts. For example, ATZ could make bearings that last even longer. We’re excited to use these at Eshino Precision to boost performance!

Smarter Binder Systems

Binders are like glue that holds ceramic powder together during CIM. New binders are easier to remove, making the process faster and cleaner. This means we can make parts like alumina insulators more efficiently. Plus, these binders help create smoother, better-quality parts for electronics.

Digital Tools and Sustainability

Digital tech, like mold flow simulations, helps us design perfect molds before we start. This saves time and reduces mistakes. Also, we’re working on eco-friendly binders and energy-saving sintering to make CIM greener. These trends align with our goal to create sustainable ceramic solutions for a better planet!

People Also Ask: Common Questions About CIM

Lots of people have questions about ceramic injection molding. At Eshino Precision, we want to answer them clearly to help you understand CIM better. Here are the top questions we hear, with simple answers!

What is Ceramic Injection Molding Used For?

CIM makes tiny, strong parts for many industries. For example, it creates dental implants for doctors, sensors for cars, and insulators for electronics. It’s also used for cool stuff like watch cases and kitchenware. Basically, CIM is everywhere!

How Does Ceramic Injection Molding Work?

CIM is like baking a super strong cake! First, we mix ceramic powder with a binder to make a gooey mix. Then, we squirt it into a mold to shape it. Next, we remove the binder with heat or chemicals. Finally, we bake the part at high temperatures (up to 1600°C) to make it hard. This process makes precise parts for aerospace and more.

What Are the Benefits of Ceramic Injection Molding?

CIM is awesome because it makes complex shapes with high precision (±0.3% accuracy). It’s also cost-effective for big orders and uses tough ceramics that resist wear and heat. This makes it great for high-strength parts in medical or energy systems.

Which Industries Use Ceramic Injection Molding?

Lots of industries love CIM! It’s used in medical for implants, automotive for sensors, aerospace for turbine blades, and electronics for insulators. Even consumer goods like jewelry use CIM for durability.

What Materials Are Used in Ceramic Injection Molding?

We use ceramics like alumina for insulation, zirconia for toughness, and silicon nitride for heat resistance. Each material is picked to match the job, like bearings or insulators.

Conclusion

Ceramic injection molding is a game-changer for making tiny, super-strong parts that work in tough conditions. From medical implants to aerospace components, CIM delivers precision and durability. At Eshino Precision, we’re experts in using CIM to create custom solutions with materials like alumina and zirconia. Plus, with the CIM market growing to $524 million by 2025, now’s the perfect time to explore this technology!

Why Choose Eshino Precision?

We know how to tackle CIM challenges, like high costs and tricky processes, to deliver top-quality parts. Our team is ready to help you with ceramic solutions for any industry, from electronics to energy. Want to learn more? Check out our blog for tips and guides!

External Resources

Want to dive deeper into ceramic injection molding? Here are some helpful resources:

- IMARC Group: Ceramic Injection Molding Market Size – Learn about market trends and growth.

- Kyocera: CIM Technology – Explore how CIM creates precise parts.

- Morgan Technical Ceramics: CIM Components – See real-world CIM applications.

Ready to Transform Your Engineering Solutions?

No industrial challenge is too complex for Eshino. From precision ceramic rods and advanced bushings to customized nozzles and other high-performance components, we engineer solutions that combine exceptional durability, thermal resistance, and precision to meet your specific needs. Whatever your industry demands, Eshino delivers tailored expertise you can trust.