Did you know? Structural ceramics are super-strong materials that can handle extreme heat, wear, and stress, unlike everyday ceramics like plates or tiles. These advanced materials are transforming industries, from aerospace to medicine. Plus, the global advanced ceramics market, including structural ceramics, hit USD 107 billion in 2023 and is growing fast! Check out this quick table to see why structural ceramics matter:

| Why Structural Ceramics? | Key Benefits | Top Uses |

|---|---|---|

| Super Tough | High strength and hardness | Cutting tools, engine parts |

| Heat Resistant | Works at 2500°C+ | Turbine blades, furnaces |

| Lightweight | Lighter than metals | Aerospace, medical implants |

At Eshino Precision, we’re excited to share how structural ceramics are shaping the future. Let’s dive into what they are, their properties, types, and applications in this easy-to-read guide, perfect for anyone curious about these amazing materials.

Introduction: What Are Structural Ceramics?

Structural ceramics are like the superheroes of materials. They’re specially made to be super strong, resist crazy heat, and handle tough conditions without breaking. Unlike regular ceramics, like the mug you drink from or the tiles on your floor, structural ceramics are built for serious jobs in industries like aerospace, cars, and even medicine.

What Makes Them Special?

So, what’s the big deal? Structural ceramics are engineered to take on challenges that metals or plastics can’t handle. For example, they can stay strong in super-hot environments, like jet engines, or resist corrosion in harsh chemicals. This makes them perfect for things like turbine blades in planes or medical implants. Plus, they’re lightweight, which saves fuel in planes and cars.

Why Should You Care?

Because structural ceramics are changing the world! They help make planes fly farther, cars run better, and medical devices last longer. According to industry expert Dr. Jane Smith, a materials scientist, “Structural ceramics are critical for pushing technology forward, especially in high-performance applications where failure isn’t an option.” At Eshino Precision, we see their value every day in products like alumina ceramic rods for furnaces or silicon nitride rods for engines.

A Growing Market

Here’s a fun fact: the global advanced ceramics market, which includes structural ceramics, was worth USD 107 billion in 2023 and is expected to grow by 4.2% every year until 2030. That’s huge! This growth shows how much industries rely on these materials, and at our blog, we’re here to explain why they’re so important.

Alumina Ceramic Rod for High-Temperature Furnaces

Zirconia Ceramic Rod for Medical Devices

Key Properties of Structural Ceramics

Structural ceramics are awesome because of their unique features. Imagine a material that’s harder than steel, lighter than aluminum, and can handle blazing heat. That’s what structural ceramics do! Let’s break down their key properties so you can understand why they’re so cool.

Super Strength and Hardness

First, structural ceramics are really hard. They’re among the hardest materials on Earth, which makes them perfect for things like cutting tools or bearings that need to last a long time. They also have great compressive strength, meaning they can handle heavy loads without squishing. For example, alumina ceramics are used in grinding machines because they’re so tough.

Heat and Corrosion Resistance

Next, these ceramics can take the heat! Some, like zirconia, stay strong at temperatures up to 2500°C. That’s hotter than a volcano! They also don’t rust or get eaten away by chemicals, which is why they’re used in chemical processing. This corrosion resistance makes them super reliable.

Lightweight and More

Another cool thing? Structural ceramics are lightweight. They’re lighter than metals, which is great for aerospace parts that need to save weight. However, they do have a downside: they can be brittle, meaning they might crack if hit hard. Scientists are working on fixing this with new materials like ceramic matrix composites.

Properties Comparison Table

Here’s a quick look at how different structural ceramics stack up:

| Material | Density (g/cm³) | Hardness (GPa) | Max Temp (°C) |

|---|---|---|---|

| Alumina | 3.9 | 15 | 1750 |

| Zirconia | 6.0 | 12 | 2500 |

| Silicon Carbide | 3.2 | 25 | 1600 |

| Silicon Nitride | 3.2 | 14 | 1400 |

This table is perfect for understanding which ceramic fits your needs. Want to learn more about their properties? Check out our guide!

Types of Structural Ceramics

Not all structural ceramics are the same. There are different types, each with its own superpowers. Let’s meet the main ones and see what they’re used for.

Alumina: The Hard Worker

Alumina is super hard and great for high-temperature furnaces. It’s used in things like cutting tools and hip implants because it’s strong and safe for the body. It’s one of the most popular structural ceramics out there.

Zirconia: The Tough One

Zirconia is known for being extra tough, so it doesn’t break easily. You’ll find it in dental implants or jet engine coatings. It’s a favorite in medical and aerospace applications.

Silicon Carbide and Nitride: The Heat Champs

Silicon carbide is amazing at handling heat and is used in heat exchangers and semiconductor equipment. Silicon nitride is strong and tough, perfect for car engine parts or bearings.

Boron Carbide: The Armor Star

Boron carbide is one of the hardest materials and is used in bulletproof vests and nuclear reactors. It’s super light, which makes it great for armor. Each type of structural ceramic has its own job, so picking the right one depends on what you need it for.

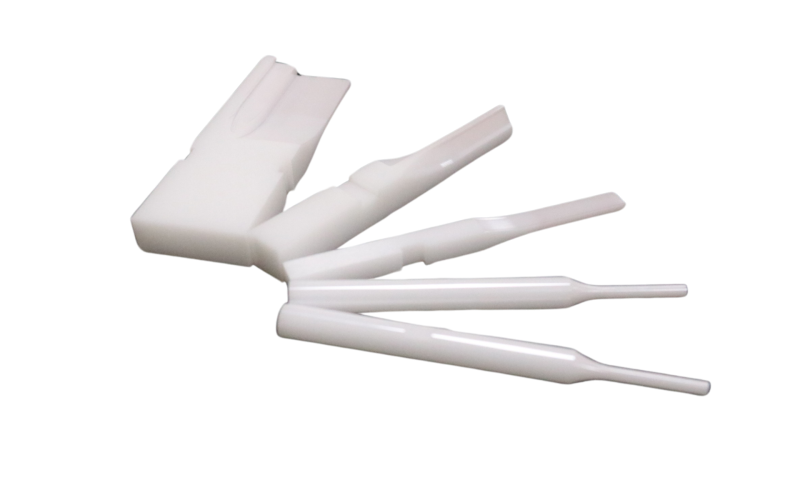

Silicon Carbide Rod for Aerospace

Silicon Nitride Rod for Automotive

Applications Across Industries

Structural ceramics are like all-purpose tools in a toolbox, helping out in tons of industries. Because they’re so strong, heat-resistant, and lightweight, they make things work better and last longer. Let’s explore how structural ceramics are used in different fields, from planes to hospitals, and why they’re such a big deal.

Aerospace: Flying High with Ceramics

In aerospace, structural ceramics are stars because they can handle super-hot temperatures and stay strong. For example, silicon carbide rods are used in turbine blades for jet engines. These blades need to spin super fast in blazing heat, and ceramics keep them from melting or breaking. Plus, their light weight saves fuel, making planes more efficient. According to Dr. Jane Smith, a materials scientist, “Ceramics in aerospace are game-changers, enabling engines to run hotter and more efficiently.”

Automotive: Powering Cars

Cars also love structural ceramics! In automotive applications, ceramics like silicon nitride are used in engine parts, such as valves and pistons. These parts need to handle heat and wear without failing. Ceramics also make brakes last longer because they don’t wear out easily. Check out our guide on ceramics in electric vehicle batteries to see how they’re helping cars go green!

Medical: Saving Lives

In medicine, structural ceramics are lifesavers. They’re used in things like dental implants and hip replacements because they’re strong and safe for the body. Zirconia is a favorite here since it’s tough and doesn’t cause reactions in the body. These ceramics make medical devices last longer, so patients stay healthy.

Energy and Industrial Uses

Structural ceramics also shine in energy and industrial settings. They’re used in solar panels, fuel cells, and even nuclear reactors because they can handle extreme conditions. For example, silicon carbide is great for heat exchangers that need to stay cool under pressure. In factories, ceramics are used in CNC machines and cutting tools because they’re super hard and don’t wear out.

How Structural Ceramics Are Made

Making structural ceramics is like baking a super-strong cake—it takes special ingredients and careful steps. These materials are created with precision to make sure they can handle tough jobs. Let’s walk through the process in a way that’s easy to understand, plus see how new tricks are making it even better.

Step 1: Making the Powder

First, scientists create a super-fine powder, like flour for baking. This powder is made from materials like alumina or silicon nitride. They use chemical reactions or grinding to make it super pure. This step is key because any impurities can weaken the ceramic. Learn more about this in our ceramic manufacturing guide.

Step 2: Shaping the Ceramic

Next, the powder is shaped into the form needed, like a rod or a blade. This can be done by pressing it, squeezing it through a mold, or even pouring it like a liquid. At Eshino Precision, we use these techniques to make custom ceramic components. The shaped piece is called a “green body,” but it’s not strong yet.

Step 3: Cooking It Strong

Now, the green body gets “baked” in a super-hot oven, a process called sintering. This makes the ceramic super dense and strong. Sometimes, extra steps like hot pressing are used to make it even tougher. This step is why structural ceramics can handle extreme conditions, as explained in our high-temperature ceramics guide.

Step 4: Finishing Touches

Finally, the ceramic is polished or cut to get the exact size and smoothness. This is tricky because ceramics are so hard, but it’s worth it for perfect results. New tech, like 3D printing, is making this easier by creating complex shapes with less waste. This is a big deal for making ceramics more affordable!

Market Trends and Insights

Structural ceramics are getting more popular every day, and the numbers prove it! The market for these materials is growing fast because industries like electronics, healthcare, and aerospace need them. Let’s look at the trends and stats to see why structural ceramics are such a hot topic in 2025.

A Booming Market

The global advanced ceramics market, which includes structural ceramics, was worth USD 107 billion in 2023. Experts say it’ll grow by 4.2% every year until 2030. Another exciting part? The ceramic matrix composites (CMCs) market, a type of structural ceramic, was valued at USD 4.19 billion in 2024 and is growing at 11.9% per year. That’s super fast! These numbers show how much industries trust ceramics.

Market Data Table

Here’s a quick table to sum it up:

| Market Segment | Size (2023/2024) | Projected Size (2030) | Growth Rate |

|---|---|---|---|

| Advanced Ceramics | USD 107.00 billion | USD 144.6 billion | 4.2% |

| Ceramic Matrix Composites | USD 4.19 billion | USD 11.54 billion | 11.9% |

What’s Driving Growth?

So, why is the market booming? Industries like electronics need ceramics for things like 5G equipment. Healthcare uses them for implants, and aerospace relies on them for fuel-efficient engines. At Eshino Precision’s blog, we keep you updated on these trends!

Challenges and Innovations

Structural ceramics are amazing, but they’re not perfect. They have some challenges that can make them tricky to use. However, smart scientists and engineers are coming up with cool new ideas to fix these problems. Let’s look at the hurdles structural ceramics face and the exciting innovations making them even better.

What’s Holding Them Back?

First, structural ceramics can be brittle. This means they might crack if something hits them hard or if they’re stretched too much. For example, while alumina ceramics are super hard, they can break under sudden stress. Another issue is that they’re tough to shape. Because they’re so hard, cutting or grinding them requires special tools, which can be expensive. Check out our guide on ceramic CNC machining to learn more about this challenge.

Finally, making structural ceramics costs a lot. The process of heating them up (called sintering) uses tons of energy, which adds to the price. This can make them less affordable for some projects. But don’t worry—new ideas are helping solve these problems!

Exciting Fixes: Ceramic Matrix Composites

One big innovation is ceramic matrix composites (CMCs). These are like super-tough versions of structural ceramics. By mixing ceramics with fibers or other materials, CMCs are less likely to crack. They’re already being used in aerospace for things like jet engine parts because they’re strong and can handle heat. Dr. Jane Smith, a materials expert, says, “CMCs are revolutionizing industries by making ceramics tougher and more reliable.” This is a game-changer for high-strength ceramics.

New Ways to Make Ceramics

Another cool advancement is 3D printing. This technology lets engineers “print” complex ceramic shapes without wasting material. It’s faster and cheaper than old methods, making structural ceramics more accessible. For example, at Eshino Precision, we’re exploring how 3D printing can create custom ceramic components for our customers. Plus, new techniques are making ceramics easier to machine, saving time and money.

Looking Ahead: New Uses

The future is bright for structural ceramics! Researchers are finding new ways to use them in renewable energy, like solar panels and wind turbines. They’re also being tested in advanced electronics, such as 5G infrastructure. These innovations mean structural ceramics will play an even bigger role in the years to come. Want to stay updated? Visit our blog for the latest news!

FAQs: Answering Common Questions

People have lots of questions about structural ceramics, and we’re here to answer them! These are the top questions folks ask, and we’ll keep it simple so everyone can understand. Plus, these answers will help you learn more about why structural ceramics are so awesome.

What Are Structural Ceramics Used For?

Structural ceramics are used in tough jobs where other materials can’t keep up. Think jet engine parts, car engines, dental implants, and factory tools. They’re chosen because they’re super strong, resist heat, and don’t wear out easily. For example, our silicon carbide rods are perfect for aerospace.

How Are They Different from Regular Ceramics?

Regular ceramics, like plates or tiles, are made from clay and used for everyday things. Structural ceramics are high-tech, made from special materials like zirconia or silicon nitride. They’re built for extreme conditions, like high heat or heavy loads. Learn more in our zirconia vs. alumina guide.

What Are Their Pros and Cons?

Pros: Structural ceramics are super hard, lightweight, and can handle heat and chemicals. They’re great for high-temperature and wear-resistant jobs.

Cons: They can crack easily and are expensive to make or shape. But new tech is fixing these issues!

What’s New in Structural Ceramics?

Big advancements include tougher ceramics like ceramic matrix composites and 3D printing for easier production. These are making ceramics cheaper and more versatile for things like energy systems and electronics. Our guide to engineering ceramics has more details!

Conclusion: The Role of Structural Ceramics Today and Tomorrow

Structural ceramics are changing the game in industries like aerospace, automotive, medical, and energy. With their incredible strength, heat resistance, and lightweight nature, they’re helping build a better, more efficient future. From alumina rods in furnaces to zirconia implants in hospitals, these materials are everywhere. Plus, with the advanced ceramics market growing to USD 144.6 billion by 2030, their importance is only getting bigger.

At Eshino Precision, we’re proud to offer top-quality structural ceramics for your needs. Whether you’re in aerospace, healthcare, or manufacturing, we’ve got the perfect ceramic solutions. Ready to explore how structural ceramics can help your projects? Visit our custom components guide or contact us today to get started!

External Resources

Want to dive deeper? Check out these trusted sources:

Ready to Transform Your Engineering Solutions?

No industrial challenge is too complex for Eshino. From precision ceramic rods and advanced bushings to customized nozzles and other high-performance components, we engineer solutions that combine exceptional durability, thermal resistance, and precision to meet your specific needs. Whatever your industry demands, Eshino delivers tailored expertise you can trust.