In the ever-evolving energy sector, our high-performance ceramic rods deliver unmatched durability and precision. Engineered to thrive under extreme temperatures, high pressures, and corrosive environments, these advanced ceramics are the backbone of critical energy systems—from nuclear reactors to thermal power plants and renewable energy installations.

Ceramic rods play a pivotal role in various energy applications, ensuring optimal performance and reliability. Here are some of the most specific and impactful applications:

Nuclear Power Plants:

Thermal Power Plants:

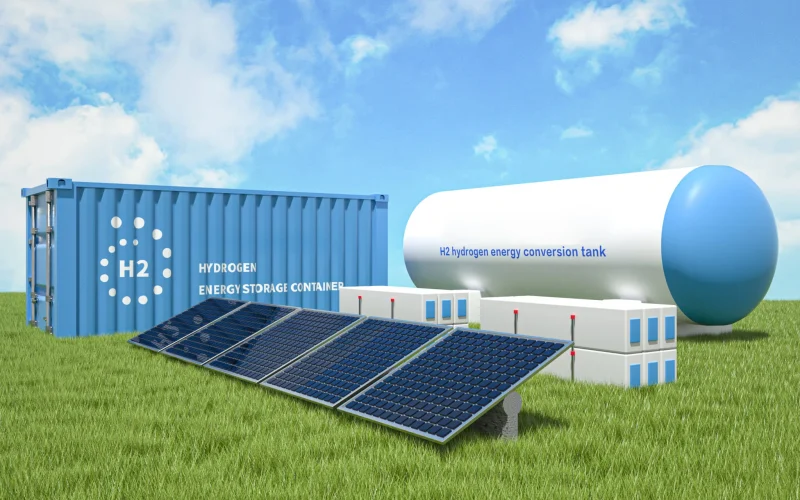

Renewable Energy Systems:

Energy Storage and Battery Systems:

Geothermal Energy:

Ceramic rods offer distinct advantages that are critical to the performance and efficiency of energy systems:

Capable of withstanding extreme heat, ceramic rods ensure stable operation in thermal power plants and CSP systems.

Designed to endure harsh environments, ceramics resist abrasive wear and chemical corrosion, reducing maintenance costs and downtime.

With high strength and toughness, ceramic rods maintain their integrity under significant mechanical stress, ensuring reliability in high-pressure applications.

Optimal heat dissipation improves the overall efficiency of energy systems by maintaining controlled temperatures in critical components.

Providing high levels of electrical insulation, ceramic rods contribute to the safety and performance of power distribution and energy storage systems.

The most commonly used ceramic rods in energy applications include zirconia, silicon nitride, silicon carbide, and alumina. Each offers unique benefits in terms of thermal stability, mechanical strength, and wear resistance.

Ceramic rods enhance efficiency by providing excellent heat management, reducing thermal losses, and maintaining structural integrity under extreme conditions, which collectively lead to better system performance and lower operational costs.

While ceramic rods may have a higher upfront cost compared to traditional materials, their long service life, reduced maintenance, and improved performance make them a cost-effective solution over the long term.

Yes, ceramic rods can be tailored in terms of size, material composition, and surface finish to meet the specific requirements of various energy systems, ensuring optimal performance and compatibility.

Their inherent material properties, including high melting points, robust chemical stability, and exceptional wear resistance, make ceramic rods ideal for environments characterized by extreme temperatures and aggressive chemicals.

Enhance the performance and reliability of your energy systems with our advanced ceramic rod solutions. Contact our experts today to discuss your requirements and receive a customized proposal tailored to your application needs.

We will get back to you within 12 hours.