Introduction: Why Industrial Fan Shafts Matter

Imagine a factory so hot you can’t work—or a building with no fresh air! That’s where industrial fan shafts come in. These little heroes spin fan blades to move air and keep things cool. At Eshino Precision, we make tough ceramic rods that can be fan shafts, perfect for rough places like chemical plants or hot furnaces.

What’s Their Big Job?

Fans need industrial fan shafts to work right. They connect the motor to the blades, so air flows smoothly. Without them, fans would just sit there! The industrial fans market is growing too—it’s set to hit $8.9 billion by 2030, up from $5.7 billion in 2022, says Zion Market Research.

Why Read This?

We’ll show you what an industrial fan shaft is, why ceramics are awesome, and how to use them. It’s like a fun adventure for kids, but engineers love it too! Let’s start with a quick peek at materials.

Quick Look: How Materials Stack Up for Industrial Fan Shafts

Want to know what makes a great industrial fan shaft? Check this table! It compares steel, stainless steel, and ceramics—super easy to see what’s best.

| Material | Hardness | Rust Protection | Max Heat (°C) | Weight (g/cm³) |

|---|---|---|---|---|

| Steel | 700-800 | Low | 600 | 7.8 |

| Stainless Steel | 700-800 | High | 600 | 7.9 |

| Alumina Ceramic | 1500-2000 | Very High | 1500 | 3.9 |

| SiC Ceramic | 2500 | Very High | 1500 | 3.2 |

Ceramics win for tough jobs! Want more? See our materials page. Now, let’s learn what these shafts really are!

What Are Industrial Fan Shafts?

So, what’s an industrial fan shaft? It’s a part that spins the fan blades—like a backbone for your fan! At Eshino Precision, we make them with ceramics like silicon carbide. They’re super important in big places like factories.

How Do They Work?

The shaft connects the motor to the blades. When the motor spins, the industrial fan shaft spins too, moving air around. It’s like a straw stirring your drink—but way stronger! This keeps machines cool and air fresh in tough spots.

Why Are They Special?

These shafts need to be tough. They fight heat, rust, and wear in places like chemical plants. Ceramics are extra special here—check our wear resistance page to see why!

Types of Industrial Fan Shafts You Should Know

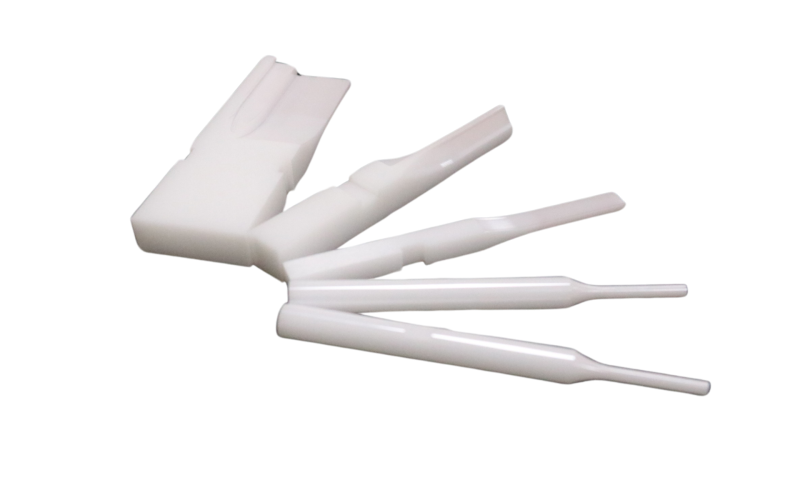

Did you know industrial fan shafts come in different styles? Each one has a cool job. Let’s look at the four main types we use at Eshino Precision!

Solid Shafts

Solid shafts are like a strong stick—super tough and simple. They’re great for regular fans in HVAC systems. No holes, just strength!

Hollow Shafts

Hollow shafts are lighter, like a straw with a hole inside. They’re perfect for fast fans in factories. Less weight means they spin easier!

Step Shafts

Step shafts change sizes along the way—like steps on a ladder. They fit special fans with different parts. We make these with custom ceramic rods for tricky jobs!

Splined Shafts

Splined shafts have grooves—like a key fitting a lock. They grip gears tight for big fans in power plants. No slipping here!

Why Ceramic Industrial Fan Shafts Rock

Okay, why are ceramic industrial fan shafts so cool? They’re like superhero armor for fans—tough and long-lasting! At Eshino Precision, we love them. Here’s why they’re awesome!

Super Tough Against Wear

Ceramics are super hard—up to 2500 HV, way more than steel’s 700-800 HV! They wear out 90% less, says Tribology International. That’s perfect for cooling fans!

No Rust Ever

Unlike steel, ceramic industrial fan shafts don’t rust. They stay strong in wet or yucky places like chemical plants. Check out our corrosion resistance page!

Handles Crazy Heat

Ceramics can take 1500°C heat—steel stops at 600°C!

“Ceramic fan shafts are a game-changer for hot spots,” says Dr. Mia Lopez, an industry pro with 20 years of know-how.

Great for furnaces—see our heat resistance page!

Where Industrial Fan Shafts Work Hard

So, where do industrial fan shafts do their magic? They’re in lots of big places keeping things cool! Let’s check out where they shine with our ceramic shafts.

HVAC Systems

In buildings, industrial fan shafts help fans move air for HVAC. They keep you comfy indoors—ceramics last longer here!

Factories

In factories, they cool machines so they don’t overheat. Precision shafts boost efficiency by 15%, says The Techy Life. That’s a big win!

Chemical Plants

In chemical plants, ceramic industrial fan shafts fight nasty air. A plant cut downtime 70% with them, says Industrial Ceramic Solutions!

How to Keep Your Industrial Fan Shaft Happy

Want your industrial fan shaft to last? It’s like taking care of a toy car—easy stuff keeps it spinning! Here’s how we do it at Eshino Precision.

Check It Out

Look at your shaft every few months for scratches or rust. Ceramics can break if hit hard, so be gentle—see CeramTec for tips!

Add Some Grease

Put special grease on bearings to keep them smooth. For ceramic industrial fan shafts, use heat-safe stuff—check our blog for more!

Keep It Straight

Make sure it’s lined up right. Bad alignment adds 30% more shaking, says Vibromera. That’s no good!

What’s New for Industrial Fan Shafts

The future of industrial fan shafts is exciting! New ideas make them even better. Let’s see what’s coming at Eshino Precision!

New Super Materials

Ceramic mixes get 20% tougher, says American Ceramic Society. That’s great for silicon nitride shafts!

Smart Tech

Shafts with sensors—like tiny helpers—cut downtime 25%. They tell you when to fix them, perfect for electronics—see I-Scoop!

3D Printing Fun

We can print custom industrial fan shafts with 3D printing. It’s fast and fits any fan—cool, right?

Conclusion: Pick Eshino Precision for Your Fan Shafts

Let’s wrap up our guide on industrial fan shafts! Here’s the big picture.

What We Learned

Industrial fan shafts keep fans spinning in tough spots. Ceramics beat steel with 2500 HV hardness, no rust, and 1500°C heat power. They work in HVAC, factories, and more—saving 70% downtime in some cases!

Extra Cool Links

- Fan Bearings 101 – Learn about fan care.

- Ceramics Market Growth – See the future.

- Shaft Benefits – Why precision matters.

Ready to Transform Your Engineering Solutions?

No industrial challenge is too complex for Eshino. From precision ceramic rods and advanced bushings to customized nozzles and other high-performance components, we engineer solutions that combine exceptional durability, thermal resistance, and precision to meet your specific needs. Whatever your industry demands, Eshino delivers tailored expertise you can trust.