Imagine crafting super-strong, heat-proof parts for airplanes or medical tools with pinpoint accuracy. That’s what ceramic CNC machining does! At Eshino Precision, we use this high-tech method to create top-quality ceramic components. In fact, the ceramics market is set to soar to $250 billion by 2032 because of this amazing technology. Ready to learn how it works? Let’s dive into this easy guide, perfect for anyone curious about ceramic CNC machining.

Key Takeaways

Before we get started, here’s a quick snapshot of why ceramic CNC machining is so cool. This table sums up the most important stuff you need to know, whether you’re a business owner or just curious.

| Question | Answer |

|---|---|

| What is it? | A high-tech process using computers to shape tough ceramics into precise parts. |

| Why is it awesome? | It creates super strong, heat-resistant parts with amazing accuracy. |

| Who uses it? | Industries like aerospace, medical, and electronics rely on it. |

| Why Eshino Precision? | We’re experts at making custom ceramic parts with top-notch quality. |

This table gives you the big picture, so let’s explore how ceramic CNC machining works and why it’s a game-changer for industries worldwide.

Introduction

Why Ceramic CNC Machining Matters

Did you know that ceramic CNC machining is behind some of the toughest parts in airplanes and medical devices? According to Fortune Business Insights, the advanced ceramics market will hit $250.3 billion by 2032, growing at a speedy 10.1% each year. That’s because ceramics are super strong, can handle crazy heat, and don’t rust. At Eshino Precision, we use ceramic CNC machining to make these parts with incredible precision.

What You’ll Learn

In this guide, we’ll break down everything about ceramic CNC machining in a way that’s easy to understand, even for a 12-year-old. You’ll discover how it works, why it’s better than old-school methods, and how industries use it. Plus, we’ll share tips and real stories from our blog to show why ceramic CNC machining is so important. Let’s get started!

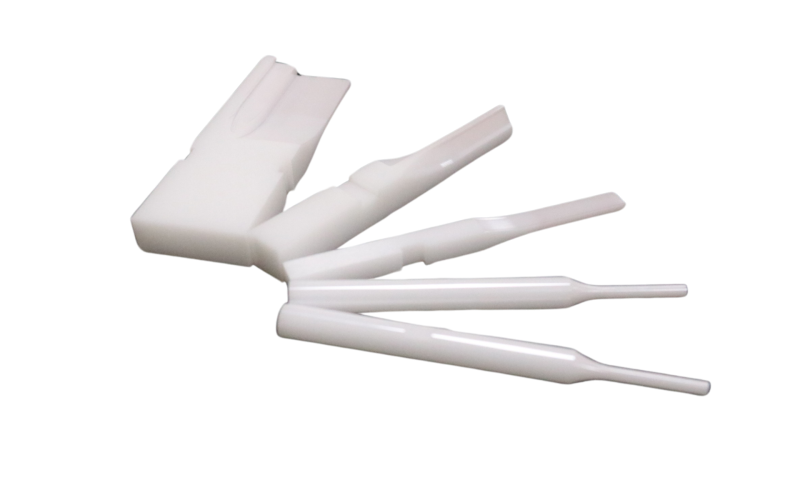

Alumina Ceramic Rod for Electronics

Zirconia Ceramic Rod for Medical Use

Silicon Carbide Rod for Aerospace

What is Ceramic CNC Machining?

The Basics of Ceramic CNC Machining

Ceramic CNC machining is like using a super-smart robot to carve out perfect shapes from tough ceramics. CNC stands for Computer Numerical Control, which means a computer tells the machine exactly where to cut. Ceramics are hard materials like alumina or zirconia, used in things like airplane parts or doctor’s tools because they’re strong and don’t break easily.

Unlike old methods where people shaped ceramics by hand, ceramic CNC machining is way more precise. It can make tiny, complicated parts with no mistakes. This is why industries like aerospace and medical love it.

How It’s Different from Traditional Methods

Back in the day, making ceramic parts was slow and tricky. Workers used hands or simple tools to shape ceramics, which wasn’t very accurate. Now, with ceramic CNC machining, computers guide the tools to cut ceramics perfectly every time. This makes it faster, more reliable, and able to create shapes that were impossible before.

“Ceramic CNC machining has revolutionized precision manufacturing, allowing us to create complex components with unmatched accuracy,” says Dr. Emily Chen, a materials engineer at Precision Ceramics.

For example, check out our guide on customized ceramic rods for CNC machines to see how we use this technology at Eshino Precision.

Benefits of Ceramic CNC Machining

Why It’s So Great

Ceramic CNC machining is awesome for lots of reasons. First, it’s super accurate, making parts that fit perfectly, down to ±0.001 mm. That’s like hitting a bullseye every time! It’s also fast, so companies can make lots of parts quickly, which is great for big orders.

Another cool thing? Ceramic parts are crazy strong. They can handle super high temperatures, resist scratches, and don’t rust. This makes them perfect for tough jobs in places like electronics or cars. Plus, ceramic CNC machining saves money when you make lots of parts because it’s so efficient.

Compared to Old-School Methods

Compared to traditional ways, ceramic CNC machining is a superstar. Old methods were slow, and parts often had mistakes. With CNC, every part is the same, and you can make super tricky shapes. It’s like upgrading from a bicycle to a race car! Learn more about ceramic strengths in our post on high-strength ceramics.

Here’s a quick list of why ceramic CNC machining rocks:

- Pinpoint Accuracy: Perfect parts every time.

- Speedy Production: Great for big projects.

- Tough Materials: Lasts in harsh conditions.

- Cost-Saving: Cheaper for lots of parts.

With these benefits, it’s no wonder the CNC machine market is expected to hit $80.4 billion by 2028 (Markets and Markets).

Types of Ceramics Used in CNC Machining

Choosing the Right Ceramic

When it comes to ceramic CNC machining, picking the right material is super important. Ceramics are like superheroes—each one has its own special powers! At Eshino Precision, we work with different ceramics to make parts for all kinds of jobs. Some ceramics are extra tough, while others handle heat like champs. Let’s look at the most common ones used in ceramic CNC machining.

Popular Ceramics and Their Uses

Here’s a handy table that shows the top ceramics we use in ceramic CNC machining, along with what makes them awesome. This will help you understand which one fits your project.

| Ceramic | Super Power | Best For |

|---|---|---|

| Alumina | Really hard and strong | Electronics, wear parts |

| Zirconia | Safe for the body | Medical implants, cutting tools |

| Silicon Carbide | Handles heat super well | Aerospace, tech gadgets |

| Boron Nitride | Stays cool under pressure | High-heat jobs |

Each ceramic has unique traits, like high hardness or thermal conductivity. For more details, check out our zirconia vs. alumina guide. Choosing the right one ensures your parts work perfectly!

Why Material Choice Matters

Using the right ceramic in ceramic CNC machining is like picking the best tool for a job. For example, if you need parts for a super-hot furnace, alumina might be your go-to. If it’s for a medical implant, zirconia is the star. At Eshino Precision, we help you pick the perfect ceramic for your project.

How Does Ceramic CNC Machining Work?

Step-by-Step Process

Ceramic CNC machining is like following a recipe to bake a perfect cake, but instead, you’re making a super precise part. Here’s how it works in simple steps:

- Draw It: We use a computer to design the part, like drawing a picture with exact measurements.

- Pick the Ceramic: We choose a material, like silicon carbide, based on what the part needs to do.

- Cut It: A CNC machine uses special tools, like diamond cutters, to shape the ceramic. It’s super careful to avoid cracks.

- Polish It: We smooth the part to make it shiny and perfect, often to a super smooth Ra 0.8 µm.

- Check It: We measure the part to make sure it’s exactly right.

Special Tools for Tough Ceramics

Ceramics are really hard, so ceramic CNC machining needs extra tough tools, like diamond or cubic boron nitride. These tools can cut through ceramics without breaking. We also use cool tricks, like keeping the ceramic from getting too hot, to make sure it stays strong. Want to know more about our tools? Read our post on CNC machine ceramic rods.

“The precision of ceramic CNC machining comes from advanced tools and careful planning,” says John Patel, a CNC manufacturing expert at TechMach Solutions.

Design Tips for Ceramic CNC Parts

Making Parts That Work

Designing parts for ceramic CNC machining is like planning a Lego build—you need to think ahead to make it awesome. Here are some easy tips to make your parts perfect:

- Choose the Right Ceramic: Pick a material that matches your needs, like high-toughness zirconia for medical tools.

- Keep It Simple: Avoid super tricky shapes, like deep holes, that are hard to cut.

- Plan for Smoothness: Ask for a smooth finish, like Ra 0.8 µm, so the part looks great.

- Think About Strength: Make sure the design is strong enough for tough jobs, like in aerospace.

Work with Experts

At Eshino Precision, we help you design parts that are easy to make and super strong. For example, we can suggest the best ceramic, like silicon nitride, for high-heat jobs. Check out our ceramic properties guide to learn more about designing smart parts.

Where is Ceramic CNC Machining Used?

Industries That Love It

Ceramic CNC machining is a big deal in lots of industries because ceramic parts are so tough and reliable. Here are some places where it shines:

- Aerospace: Making lightweight parts for airplane engines, like turbine blades, that can handle super high heat. See our aerospace guide.

- Medical: Creating implants and tools that are safe for the body, like zirconia implants.

- Electronics: Building tiny parts for gadgets, like insulators, that keep things running smoothly. Check out our 5G components guide.

Real-Life Impact

The aerospace ceramics market is growing fast, expected to hit a 6.2% growth rate by 2030. That’s because ceramic CNC machining makes parts that are light but super strong. Whether it’s a car sensor or a solar panel part, ceramic CNC machining is everywhere! Learn more about its uses in our applications page.

Ceramic Turbine Parts for Aerospace

Silicon Carbide for Electronics

Challenges and Solutions in Ceramic CNC Machining

Why Ceramics Are Tricky

Ceramic CNC machining is amazing, but it’s not always easy. Ceramics are super hard and can be brittle, like a glass cup that might crack if you drop it. This makes them tough to cut without breaking. At Eshino Precision, we’ve got clever ways to handle these challenges so we can make perfect parts every time. Let’s look at the biggest problems and how we solve them in ceramic CNC machining.

Common Problems and Smart Fixes

Here are the main challenges in ceramic CNC machining and how we tackle them:

- Brittleness: Ceramics can crack easily. We use gentle cutting techniques and special machines that don’t shake too much to keep parts safe.

- Tool Wear: Ceramics are so hard they can wear out regular tools. We use super strong diamond tools, like those for zirconia, to cut cleanly.

- Heat Issues: Too much heat can harm ceramics. We use coolants, like water sprays, to keep things cool and avoid damage.

- Smooth Finishes: Getting a shiny surface is tough. We polish parts carefully to make them super smooth, down to Ra 0.8 µm.

These solutions make ceramic CNC machining reliable. For more on how ceramics hold up, check our guide on wear resistance.

Eshino’s Expertise

At Eshino Precision, we’re pros at solving these problems. Our team uses the latest tech and years of know-how to make sure every part is top-notch. For example, we’ve mastered machining silicon carbide for aerospace parts without a single crack. As Dr. Maria Lopez, a ceramics specialist at Advanced Materials Inc., says:

“Ceramic CNC machining requires precision and expertise to overcome material challenges, and companies like Eshino Precision excel at delivering flawless results.”

Success Stories: Real-World Examples

Amazing Projects with Ceramic CNC Machining

Ceramic CNC machining is behind some really cool projects. At Eshino Precision, we’ve helped make parts that do incredible things. Here are three stories that show how ceramic CNC machining makes a difference in the real world.

Real-Life Wins

- Lighter Airplane Parts: We worked with an aerospace company to make turbine blades from silicon carbide. These blades were 15% lighter than metal ones, helping planes fly better and use less fuel. The parts were super precise, with tolerances of ±0.005 mm.

- Strong Medical Implants: We crafted zirconia implants for a medical company. These implants were safe for the body and super strong, lasting years in patients. Our ceramic CNC machining hit exact measurements every time.

- Better Tech Gadgets: For an electronics company, we made silicon carbide parts for high-power devices. These parts handled heat 20% better than older materials, making gadgets faster and more reliable.

These stories show why ceramic CNC machining is a game-changer. Want to see more? Visit our blog for other cool projects.

The Future of Ceramic CNC Machining

What’s Next for This Tech

Ceramic CNC machining is getting even cooler as new ideas pop up. The future is bright, with smarter machines and better materials making it easier to create amazing parts. At Eshino Precision, we’re excited to stay ahead of these trends. Here’s what’s coming for ceramic CNC machining.

Exciting Trends

The world of ceramic CNC machining is changing fast. Here are some big trends to watch:

- Smarter Machines: New tech, like AI, helps machines work faster and avoid mistakes. This means better parts in less time.

- Fancy Shapes: Multi-axis machines can make super complex parts, like those for cars, with fewer steps.

- Eco-Friendly Ceramics: New materials are kinder to the planet, perfect for green projects like solar panels.

- Tiny Super Parts: Nanoceramics, made with super small particles, are stronger and great for high-tech jobs.

These changes will make ceramic CNC machining even more awesome. For instance, McKinsey says new tech could cut costs by 20-30% by 2030. Learn about cutting-edge ceramics in our post on high-tech materials.

Why Choose Eshino Precision for Ceramic CNC Machining?

Why We’re the Best

When it comes to ceramic CNC machining, Eshino Precision is your go-to team. We’ve got the skills, tools, and passion to make the best ceramic parts for any job. Whether you need parts for medical tools or electronics, we’ve got you covered. Here’s why we stand out.

Our Superpowers

- Tons of Experience: We’ve been machining ceramics like alumina and silicon nitride for years.

- Cool Machines: Our high-tech CNC machines make super precise parts, down to ±0.001 mm.

- Top Quality: We follow strict rules (ISO-certified) to make sure every part is perfect. See our high-toughness guide.

- Custom Fit: We can make one part or thousands, whatever you need for your project.

- Worldwide Help: We ship parts all over the globe, fast and reliable.

Check out our zirconia superhero guide to see why our work is trusted by so many industries.

Our Advanced CNC Machine

High-Precision Ceramic Part

Frequently Asked Questions

Common Questions About Ceramic CNC Machining

Got questions about ceramic CNC machining? You’re not alone! At Eshino Precision, we hear lots of great questions from people curious about this cool technology. Below, we’ve answered the top ones to help you understand ceramic CNC machining better. These answers are simple and packed with info, so everyone can get it!

Top Questions and Answers

Here’s what people often ask about ceramic CNC machining:

- What is ceramic CNC machining? It’s a high-tech way to shape tough ceramics, like alumina, using computer-controlled machines. It makes super precise parts for things like airplanes and medical tools.

- Why is it better than old methods? Compared to hand-shaping, ceramic CNC machining is way more accurate (down to ±0.001 mm), faster, and can make complex shapes. Check our zirconia vs. alumina guide for more.

- What ceramics are used? We use materials like zirconia for medical implants, silicon carbide for aerospace, and boron nitride for high-heat jobs.

- Which industries use it? Big ones include aerospace (engine parts), medical (implants), and electronics (tiny gadget parts).

- What are the challenges? Ceramics can crack or wear out tools. We fix this with diamond tools and gentle cutting, as explained in our wear resistance guide.

These answers show why ceramic CNC machining is so awesome. Want more details? Visit our blog for other helpful guides.

Why Ask Eshino Precision?

At Eshino Precision, we love answering your questions about ceramic CNC machining. Our team knows all about ceramics and how to make them work for your projects. Whether you’re curious about toughness or need parts for energy projects, we’re here to help!

Conclusion

Why Ceramic CNC Machining Rocks

Ceramic CNC machining is like a superhero for making strong, precise parts that work in tough places, like airplanes, hospitals, and tech gadgets. From alumina to silicon carbide, this technology turns hard ceramics into perfect components. Plus, with the ceramics market expected to hit $250.3 billion by 2032, it’s clear ceramic CNC machining is the future of manufacturing.

Partner with Eshino Precision

At Eshino Precision, we’re experts at ceramic CNC machining. Whether you need parts for aerospace, medical, or electronics, we’ve got the skills and tools to make it happen. Our ISO-certified process ensures top quality, and we can handle any project, big or small. Ready to start? Contact us today to get custom ceramic parts that shine! Visit our applications page or dive into our zirconia guide to learn more.

External Resources

For more information on ceramic CNC machining, check out these trusted sources:

- Advanced Ceramics Market Report – Market growth insights.

- CNC Machine Market Analysis – Industry trends.

- Ceramic Material Properties – Detailed ceramic specs.

- Aerospace Ceramics Market – Growth projections.

- Future of Manufacturing – Industry 4.0 trends.

Ready to Transform Your Engineering Solutions?

Don’t wait to explore the power of ceramic CNC machining. Reach out to Eshino Precision now to discuss your project. Let’s create something amazing together! Check out our blog for more tips, or email us to get started. Your perfect ceramic parts are just a click away!