Key Takeaway Table: Ceramic Bolts vs. Metal Bolts

| Property | Ceramic Bolts | Metal Bolts |

|---|---|---|

| Max Temperature | Up to 2,200°C | Typically <1,000°C |

| Corrosion Resistance | Excellent | Varies (e.g., stainless steel) |

| Electrical Conductivity | Non-conductive | Conductive |

| Toughness | Brittle | High |

| Weight | Lighter (some ceramics) | Heavier |

| Cost | Higher | Lower |

Imagine a bolt that can handle scorching heat, resist rust, and stay safe around electricity. That’s a ceramic bolt! At Eshino Precision, we specialize in these tough fasteners for extreme jobs. Whether you’re building aerospace engines or medical devices, ceramic bolts are game-changers. Let’s explore what makes them special, why they’re awesome, and how to pick the right ones for your projects in this easy-to-read guide!

What Are Ceramic Bolts?

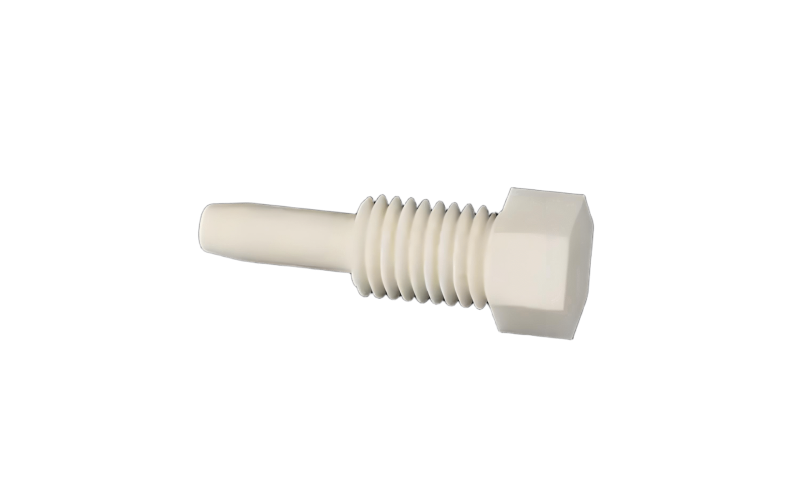

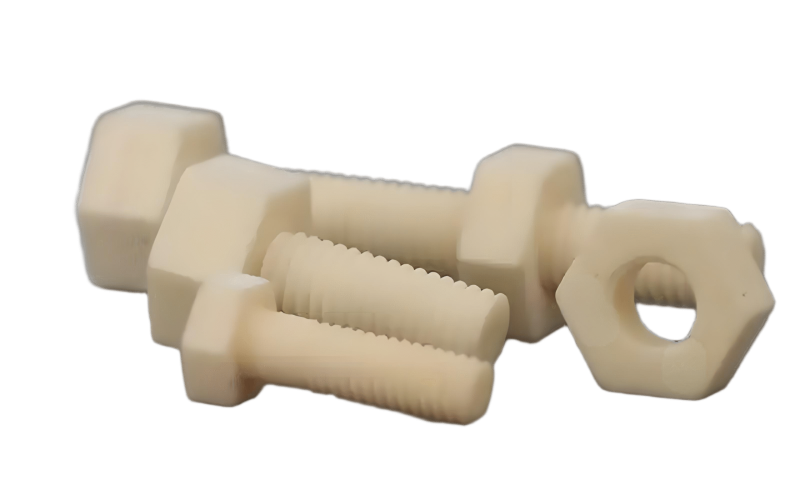

Definition and Basics

Ceramic bolts are super-strong fasteners made from materials like alumina, zirconia, or silicon carbide. Unlike regular metal bolts, they’re designed for crazy tough conditions. Think places with super high heat, harsh chemicals, or where electricity needs to stay under control. These bolts don’t rust, don’t conduct electricity, and can handle temperatures up to 2,200°C. That’s hotter than a volcano!

Why Are They Different?

Metal bolts melt or rust in extreme settings, but ceramic bolts stay strong. For example, in aerospace or medical equipment, they’re a perfect fit because they’re tough and safe. Plus, they’re lighter than many metals, which is great for things like planes or cars. At Eshino Precision, we craft these bolts to meet your toughest challenges.

Zirconia Ceramic Bolt

Zirconia Rod for Medical Use

Advantages of Ceramic Bolts

Super Powers of Ceramic Bolts

Ceramic bolts have some amazing features that make them stand out. First, they can handle super high temperatures. For example, zirconia bolts can take up to 2,200°C, while alumina handles 1,650°C. That’s way hotter than most metal bolts can manage. Second, they’re awesome at fighting corrosion. Acids, salts, or solvents? No problem—ceramic bolts stay strong.

More Cool Benefits

Another big win is electrical insulation. Since they don’t conduct electricity, they’re perfect for high-voltage machines like MRI scanners. Plus, they’re super hard—up to 9.5 on the Mohs scale—so they don’t wear out easily. And guess what? They’re lighter than many metals, which helps in cars or planes. But be careful—they’re brittle, so don’t tighten them too hard!

“Ceramic bolts are a game-changer for industries needing reliability in extreme conditions. Their ability to resist heat and corrosion is unmatched.” – Dr. Jane Carter, Materials Engineer

Applications of Ceramic Bolts

Where Do They Shine?

Ceramic bolts are used in some of the coolest industries. In aerospace, they hold turbine engines together where it gets super hot. For medical gear like MRI machines, their non-magnetic nature keeps things safe. In chemical plants, they stand up to nasty chemicals without rusting. They’re also big in electronics for insulating high-voltage systems.

Other Awesome Uses

Don’t forget automotive—lightweight ceramic bolts help cars save fuel. In energy systems like power plants, they handle extreme heat. Even in super clean semiconductor labs, ceramic bolts keep things pure by not releasing gases. Wherever conditions are tough, ceramic bolts are the heroes!

Types of Ceramic Materials

Meet the Materials

Not all ceramic bolts are the same. They’re made from different materials, each with its own superpowers. Alumina is super hard and affordable, great for up to 1,650°C. Zirconia is tougher and can handle 2,200°C, perfect for heavy-duty jobs. Silicon carbide is awesome for heat conductivity and wears well up to 1,600°C.

Which One’s Best?

Here’s a quick look at how they compare:

| Material | Max Temp (°C) | Key Strength |

|---|---|---|

| Alumina (Al₂O₃) | 1,650 | Hardness, cost-effective |

| Zirconia (ZrO₂) | 2,200 | Toughness, durability |

| Silicon Carbide (SiC) | 1,600 | Heat conductivity, wear resistance |

Need help picking? Check out our zirconia vs. alumina guide for more tips!

How to Choose the Right Ceramic Bolt

Finding the Perfect Fit

Choosing the right ceramic bolt is like picking the best tool for a job. First, think about the heat. If your project gets hotter than 1,650°C, go for zirconia because it can handle up to 2,200°C. For cooler but still hot jobs, alumina works great and saves money. Also, consider thermal conductivity—silicon carbide is awesome if you need heat to move through the bolt.

Other Things to Check

Next, look at stress. If your bolt will face a lot of pushing or pulling, zirconia’s toughness is your best bet. For electrical insulation, all ceramic bolts are great since they don’t conduct electricity. Also, check the chemicals in your project. Ceramic bolts resist most acids, but avoid hydrofluoric acid—it’s their kryptonite! Finally, think about your budget. Alumina is cheaper, while zirconia costs more but lasts in tough spots. Need custom sizes? We at Eshino Precision can help with sizes like M2 to M8.

Pro Tip

Always match the bolt to your project’s needs. For example, in aerospace, zirconia’s heat resistance is a must. Check our material comparison guide for more help!

Installation and Maintenance Tips

Installing Ceramic Bolts Safely

Installing ceramic bolts needs a gentle touch because they’re brittle. If you tighten them too much, they can crack. For example, a 4-40 alumina bolt should only get 2.4 lb-in. of torque. Always follow the manufacturer’s guide to avoid trouble. Also, ceramic bolts expand less than metals when heated, so be careful when mixing them with metal parts to prevent stress. At Eshino Precision, we recommend using a torque wrench for precision.

Keeping Them in Top Shape

The good news? Ceramic bolts are low-maintenance. Thanks to their corrosion resistance and wear resistance, they last a long time. Just check them now and then for cracks, especially in high-stress jobs like chemical processing. A quick inspection can save you from big problems later. Plus, their chemical stability means they won’t react with most substances.

Recent Innovations in Ceramic Bolts

Cool New Tech

The world of ceramic bolts is getting exciting! One big innovation is 3D printing. This lets us make custom ceramic bolts for tricky designs, perfect for aerospace or semiconductor needs. Another cool advance is new ceramics that handle even hotter temperatures, like in jet engines. These are super tough and keep up with the latest tech demands.

Stronger and Smarter

Scientists are also mixing ceramics with fibers to make composite bolts. These are stronger and great for heavy-duty jobs. At Eshino Precision, we’re keeping up with these trends to bring you the best bolts. For example, our silicon carbide bolts are perfect for high-wear spots. Innovations like these make ceramic bolts a top choice for future projects.

“3D-printed ceramic bolts are revolutionizing custom applications, offering unmatched precision for extreme environments.” – Dr. Mark Liu, Aerospace Materials Expert

Market Trends

Growing Demand

The ceramic fasteners market is on fire! In 2023, it was worth about USD 1.2 billion, and by 2024, some say it hit USD 2.5 billion. Experts predict it’ll grow to USD 4.1 billion by 2033, with a growth rate of 6.5–7.5% every year. Why? Industries like aerospace, automotive, and electronics need bolts that can handle extreme conditions. Ceramic bolts are stepping up to the challenge!

Why It’s Booming

New tech, like electric cars and 5G networks, is driving demand for ceramic components. Plus, energy systems need bolts that can take the heat. At Eshino Precision, we’re ready to meet this demand with top-quality ceramic bolts. The future looks bright, and we’re excited to be part of it!

Common Questions About Ceramic Bolts

Top Questions Answered

People often ask about ceramic bolts. Here are the answers:

- What are they used for? They’re for high-heat, corrosive, or insulating jobs, like aerospace engines or MRI machines.

- Are they stronger than metal? They’re great for squeezing forces but brittle, so metals are tougher for impacts.

- How hot can they get? Up to 2,200°C—way hotter than most metals!

- What’s the downside? They’re brittle and pricier, so handle with care.

- Where to buy? Check out Eshino Precision or other suppliers like Extreme Bolt.

More Curious Facts

Did you know ceramic bolts are made from materials like alumina or zirconia? They’re also non-conductive, perfect for electronics. If you’re wondering about high-temperature resistance, they’re unbeatable for furnaces or jet engines. Got more questions? Our blog has tons of answers!

Conclusion

Why Ceramic Bolts Matter

Ceramic bolts are the superheroes of fasteners, tackling heat, corrosion, and electricity like no other. Whether you’re working in aerospace, medical, or chemical industries, these bolts deliver. At Eshino Precision, we’re proud to offer high-quality ceramic bolts that meet your toughest needs. With innovations like 3D printing and a booming market, now’s the time to upgrade your fasteners.

External Resources

Ready to Transform Your Engineering Solutions?

No industrial challenge is too complex for Eshino. From precision ceramic rods and advanced bushings to customized nozzles and other high-performance components, we engineer solutions that combine exceptional durability, thermal resistance, and precision to meet your specific needs. Whatever your industry demands, Eshino delivers tailored expertise you can trust.