Introduction to Custom Ceramic Components

Have you ever wondered how super-strong parts are made for things like medical tools or airplane engines? Custom ceramic components are the answer! These are special parts made just for a specific job, using tough materials like alumina or zirconia. Unlike regular parts, they’re designed to fit perfectly, making them awesome for industries like medical, aerospace, and electronics. At Eshino Precision, we create these parts to solve tough problems!

What Makes Them Special

Custom ceramic components are cool because they’re made to match exactly what you need. For example, a medical device might need a zirconia implant that’s safe for the body. Ceramics are super hard and can handle crazy heat, perfect for high-temperature jobs. Plus, the technical ceramics market is growing fast—it’s expected to hit $92.1 billion in 2025! That shows how important these parts are.

Eshino Precision’s Role

At Eshino Precision, we’re experts at making custom ceramic solutions. We use fancy tools like CNC machining to create parts that are just right. Whether it’s for car sensors or 5G equipment, we make sure every part is top-notch. “Custom ceramics are key to solving unique engineering challenges,” says Dr. Sarah Kim, a ceramics specialist at TechMat Solutions.

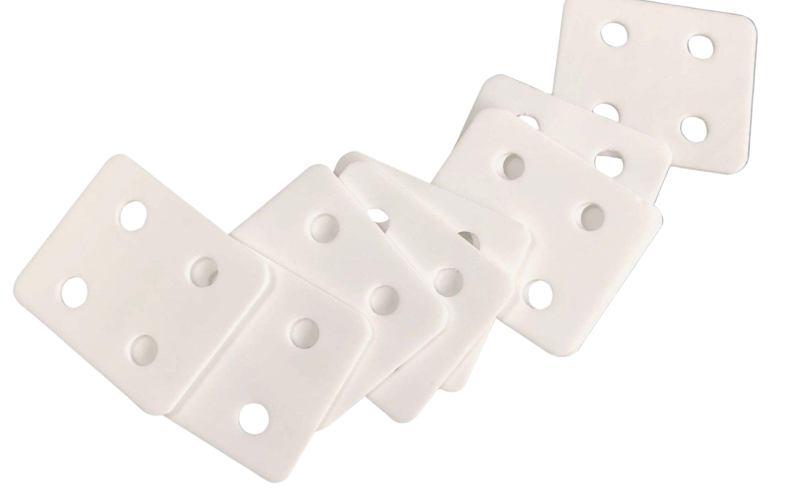

Alumina Part for Electronics

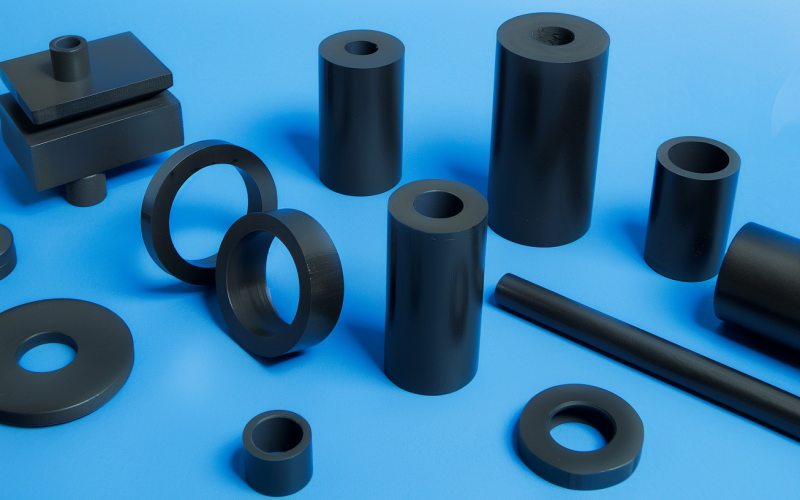

Zirconia Plunger for Medical

Key Takeaways: Why Choose Custom Ceramic Components

Want to know why custom ceramic components are so great? Check out this table—it sums up the best reasons to use them!

| Benefit | Why It’s Awesome |

|---|---|

| Perfect Fit | Made just for your project, no extra fixes needed. |

| Super Tough | Resists heat, wear, and corrosion for long life. |

| Saves Money | Less waste and fewer adjustments for big orders. |

| Boosts Performance | Improves systems like electronics or engines. |

This table shows why custom ceramic components are a smart choice. Let’s dive into their benefits next!

Benefits of Custom Ceramic Components

Custom ceramic components are like superheroes for tough jobs. They’re made to fit your needs perfectly, and they’re super strong! At Eshino Precision, we love how these parts help industries like medical and automotive. Here’s why they’re so awesome.

Perfect Fit for Your Project

Custom components are designed just for you. For example, a silicon nitride bearing can be made to fit an aerospace engine exactly. This means no extra cutting or tweaking, saving you time. A perfect fit also makes your product work better!

Super Strong Materials

Ceramics have cool powers like high hardness and wear resistance. For instance, zirconia is tough and safe for medical implants. These properties make parts last a long time, even in harsh conditions.

Saves Money for Big Orders

Making custom parts can cost a bit upfront, but it’s a great deal for lots of parts. Why? Because they come out almost perfect, so you don’t need extra work. This is awesome for car parts or electronics, where you need many pieces.

Makes Things Work Better

Custom designs can make your systems shine. For example, an alumina insulator can improve data center cooling by keeping heat in check. This boost helps your products perform at their best!

Applications Across Industries

Custom ceramic components are used in tons of cool places! From medical tools to airplane parts, these components are super versatile. At Eshino Precision, we make parts for all kinds of industries. Let’s see where they’re used!

Medical Tools and Implants

In the medical world, custom ceramics are a big deal. For example, zirconia is used for dental implants because it’s safe and strong. These parts meet tough rules like ISO 13356, so doctors trust them. We make medical components that help people feel better!

Aerospace and Cars

Airplanes need parts that handle heat, like silicon carbide engine pieces. In cars, custom sensors improve gas mileage, especially in electric vehicles. These parts are tough and last a long time.

Electronics and More

Electronics use ceramics for insulators and heat sinks, like alumina in phone circuits. Industrial tools, like silicon nitride cutters, also use custom parts. Even fancy watches use ceramics for style and strength!

Materials Used in Custom Ceramic Components

Custom ceramic components are made from special materials that are super strong and perfect for tough jobs. At Eshino Precision, we pick the best ceramics, like alumina or zirconia, to make parts that work great. Each material has its own superpowers! Let’s check them out.

Top Materials for Custom Parts

Here’s a table showing the cool materials we use for custom ceramic components and what they’re good for:

| Material | Cool Features | Best Uses |

|---|---|---|

| Alumina | Super hard, great insulator | Electronics, wear parts |

| Zirconia | Tough, safe for bodies | Medical implants |

| Silicon Carbide | Handles high heat | Aerospace parts |

| Silicon Nitride | Resists heat shocks | Bearings, engines |

Why These Materials Rock

Each material is picked for its special traits. For example, alumina is awesome for electronics because it stops electricity. Zirconia is great for medical stuff since it’s strong and safe. “Choosing the right ceramic material is like picking the perfect tool for the job,” says Dr. Mark Liu, a materials engineer at Ceramic Innovations. We make sure your parts are perfect!

Eshino’s Material Expertise

At Eshino Precision, we know all about ceramics like silicon carbide and silicon nitride. We help you choose the best one for your project, whether it’s for aerospace or cars. Check out our materials page to learn more!

Manufacturing Processes

Making custom ceramic components is like building a super cool toy—it takes special steps to get it right! At Eshino Precision, we use awesome methods to create parts that are strong and precise. From CNC machining to 3D printing, we’ve got it all. Let’s see how we do it!

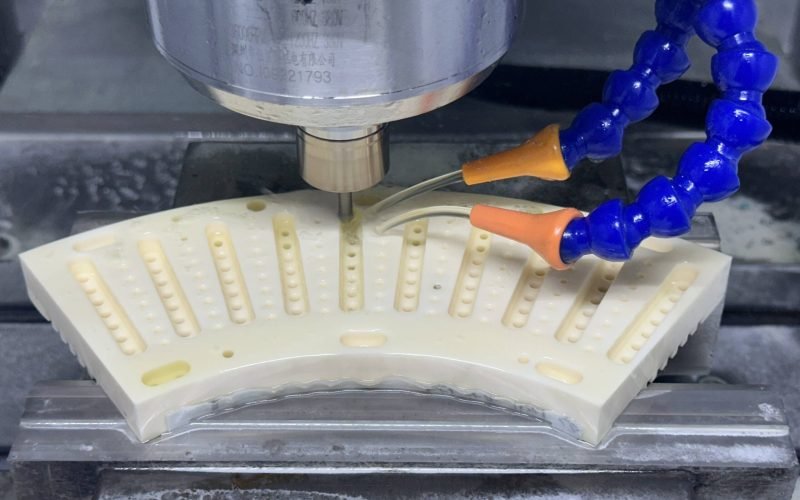

CNC Machining

CNC machining is like using a super-smart robot to carve ceramics. It’s great for making parts with exact sizes, like CNC machine components. This method ensures every part is perfect for semiconductor equipment.

Ceramic Injection Molding

Pressing and 3D Printing

Pressing squishes ceramic powder into shapes, great for simple parts. Meanwhile, 3D printing is like magic—it builds parts layer by layer for unique designs. We use it for prototypes or small runs, perfect for optical components.

Finishing Touches

After shaping, we polish or grind parts to make them smooth and shiny. This is super important for things like fan shafts that need a perfect surface. Our finishing makes sure every part is ready for action!

Design Considerations

Designing custom ceramic components is like planning a cool project—you need to think carefully! At Eshino Precision, we help you make parts that work great and don’t break. Here’s what we think about when designing your components.

Picking the Right Material

Choosing the best material is key. For example, do you need heat management or corrosion resistance? We might pick silicon carbide for furnace parts. Our team helps you decide!

Smart Shapes

Ceramics can break if they’re too thin or sharp. So, we avoid pointy corners and make shapes that stay strong. This is super important for parts like motor shafts that need to last.

Getting the Size Just Right

We make sure parts are the right size without costing too much. For instance, fan shafts need exact sizes to spin smoothly. We balance precision and price to keep you happy!

Smooth Surfaces

Some parts need a super smooth surface to work well, like wear-resistant tools. We polish them carefully to make sure they’re perfect for mechanical systems.

Quality Control and Standards

At Eshino Precision, we make sure every custom ceramic component is super high quality. We check them carefully so they work perfectly in things like medical devices or airplanes. Here’s how we keep our parts awesome!

Checking Every Part

We use special tools to measure parts and test their strength. For example, we might use X-rays to check inside semiconductor components. This makes sure there are no tiny flaws.

Following Rules

Some industries have strict rules, like ISO 13485 for medical parts or AS9100 for aerospace. We follow these to make sure our ceramic bolts and other parts are safe and reliable.

Eshino’s Quality Promise

We’re super serious about quality. Every part, from fan axles to high-strength components, is tested to be the best. You can trust us to deliver parts that work great every time!

Market Trends and Statistics

The world of custom ceramic components is growing fast! More industries are using these super-strong parts for cool things like electronics and medical tools. At Eshino Precision, we’re excited to be part of this boom. Let’s look at some awesome numbers and trends!

How Big Is the Market?

The technical ceramics market, which includes custom ceramic components, was worth $88.1 billion in 2024. Experts say it’ll hit $92.1 billion in 2025, growing at 4.52% each year. By 2033, it could reach $133.9 billion! Here’s a quick table to show the growth:

| Year | Market Size (USD Billion) |

|---|---|

| 2024 | 88.1 |

| 2025 | 92.1 |

| 2033 | 133.9 |

Why Is It Growing?

Lots of industries need custom ceramic components. For example, electronics use them for 5G equipment. Also, medical devices and cars want strong parts. New ideas like 3D printing are making ceramics even cooler! “The demand for custom ceramics is skyrocketing due to their precision,” says Dr. Emma Patel, a market analyst at CeramTech Insights.

Eshino’s Place in the Market

At Eshino Precision, we’re leading the way with high-strength ceramics. We make parts for growing fields like energy and semiconductors. Our work helps keep up with these exciting trends!

Success Stories

Custom ceramic components can do amazing things! At Eshino Precision, we’ve helped lots of companies make their products better. While we keep some stories private, here are some examples of how our parts make a difference. You can read more on our blog!

Helping Doctors

One company used our zirconia implants for dental work. These custom components were super strong and safe, helping patients smile again. They fit perfectly, so doctors could work faster!

Boosting Airplanes

An aerospace company needed silicon carbide parts for engines. Our custom components handled high heat, making planes more efficient. This saved fuel and helped the planet!

Powering Electronics

We made alumina insulators for a tech company’s electronics. These parts kept devices cool and safe, perfect for data centers. Our precision made their products awesome!

How to Order from Eshino Precision

Want your own custom ceramic components? Ordering from Eshino Precision is super easy! We make it simple to get parts for things like medical devices or car engines. Here’s how it works.

Easy Steps to Order

Follow these steps to get your custom parts:

- Contact Us: Visit ceramicrod.com or give us a call.

- Tell Us What You Need: Share drawings or details about your project.

- Talk to Our Experts: We suggest the best materials, like alumina.

- Get a Quote: We send you a price that fits your needs.

- We Make It: Using CNC machining or other methods.

- Check and Send: We test every part and ship it to you!

Why Pick Eshino?

We’re awesome at making high-strength parts. Our team cares about quality and works hard to make you happy. Whether it’s for energy or optical systems, we’ve got the skills to deliver!

Ready to Start?

Ordering is quick and fun! We help you every step of the way to create custom ceramic solutions. Contact us today to get started on your project!

Common Questions About Custom Ceramic Components

People have lots of questions about custom ceramic components. At Eshino Precision, we want to answer them simply so everyone understands. Here are the top questions we hear!

What Are the Benefits?

Custom components fit perfectly, use tough materials like zirconia, and save money. They make products better, like wear-resistant tools.

How Do I Pick a Material?

Think about what you need, like heat resistance. We help choose materials, like silicon nitride for bearings.

How Long Does It Take?

It depends, but usually a few weeks to months. Complex parts like fan shafts might take longer. We’ll give you a timeline!

Can I Order Just a Few?

Yes! We make small batches or prototypes, great for 3D printing projects.

What Affects the Cost?

Costs depend on the material, design, and how many you need. Custom parts save money over time for car parts.

Are There Design Limits?

Ceramics can break if too thin. We design tough parts to avoid problems.

How Do You Check Quality?

Can They Handle Heat?

Yes! Silicon carbide is awesome for furnaces.

Are They Good for Medical Use?

Expanded Introduction to Custom Ceramic Components

Custom ceramic components are like magic puzzle pieces made just for your project! These parts are crafted from super-tough materials like alumina or zirconia to fit perfectly in things like medical tools or airplane engines. Unlike regular parts, they’re designed for your exact needs, making them super special. At Eshino Precision, we love creating these components to help solve big problems!

Why They’re a Big Deal

Custom ceramic components are awesome because they can handle tough jobs. For example, they’re used in medical implants that need to be safe and strong. Also, the technical ceramics market is growing—it’s expected to hit $92.1 billion in 2025! This shows how much industries trust ceramics for their high-strength powers.

How Eshino Makes Them

At Eshino Precision, we use cool tricks like CNC machining to shape ceramics. We work with you to make sure every part is perfect, whether it’s for electronics or cars. Our team is all about quality, so your custom components rock!

Expanded Benefits of Custom Ceramic Components

Custom ceramic components are superstars because they’re made just for you! They help make products better and save money. At Eshino Precision, we create these parts for industries like medical and energy. Let’s dive deeper into why they’re so great!

Fit Like a Glove

Custom components are designed to match your project perfectly. For example, a silicon nitride bearing fits an aerospace system with no extra work. This saves time and makes everything run smoothly!

Tough as Nails

Ceramics have amazing features like wear resistance and heat resistance. For instance, zirconia is awesome for medical tools because it lasts forever. These parts stay strong no matter what!

Save Money Over Time

While custom parts cost a bit to design, they’re a bargain for big orders. They come out almost perfect, so you don’t need extra fixes. This is great for car sensors or 5G equipment.

Boost Your Product

Custom designs make systems work better. For example, an alumina insulator can keep data centers cool. This makes your products faster and more reliable!

Expanded Applications Across Industries

Custom ceramic components are everywhere! They’re used in medical devices, airplanes, and even fancy watches. At Eshino Precision, we make parts for all kinds of cool industries. Let’s explore where they shine!

Medical Marvels

In medicine, ceramics like zirconia are used for implants and tools. They’re safe and strong, meeting tough rules like ISO 13356. For example, dental implants help people chew better!

Aerospace and Cars

Airplanes use silicon carbide parts to handle heat. In cars, custom sensors make electric vehicles run better. These parts are tough and save energy!

Electronics and Beyond

Electronics love ceramics for insulators, like alumina in phone circuits. Industrial tools and even food processing equipment use ceramics for durability. They’re also in stylish watches!

Conclusion

Custom ceramic components are the secret sauce for making awesome products! From medical implants to aerospace engines, these parts are strong, precise, and made just for you. At Eshino Precision, we use materials like alumina and silicon nitride to create top-quality solutions. With the ceramics market hitting $92.1 billion in 2025, now’s the time to jump in!

Why Eshino Precision?

We’re experts at making high-strength parts that last. Our team helps you every step, from picking materials to final checks. Whether it’s for electronics or energy, we deliver parts that shine!

External Resources

Want to learn more about custom ceramic components? Here are some great places to look:

- IMARC Group: Technical Ceramics Market – See market growth and trends.

- Grand View Research: Advanced Ceramics – Learn about ceramics in industries.

- Kyocera: Advanced Ceramics – Explore ceramic applications and tech.

Ready to Transform Your Engineering Solutions?

No industrial challenge is too complex for Eshino. From precision ceramic rods and advanced bushings to customized nozzles and other high-performance components, we engineer solutions that combine exceptional durability, thermal resistance, and precision to meet your specific needs. Whatever your industry demands, Eshino delivers tailored expertise you can trust.