Wow, did you know? Machining alumina ceramic is like cutting through a super-hard rock! It’s tough, but it makes amazing parts for phones, planes, and even medical implants. The alumina ceramics market is worth USD 43.57 billion in 2025! Here’s a quick table to show why machining alumina ceramic is so cool:

| Why It’s Awesome | Key Fact | Where It’s Used |

|---|---|---|

| Super Hard | 9 on Mohs scale | Cutting tools, insulators |

| Heat Resistant | Up to 1750°C | Furnaces, aerospace |

| Long-Lasting | Wear-resistant | Medical implants |

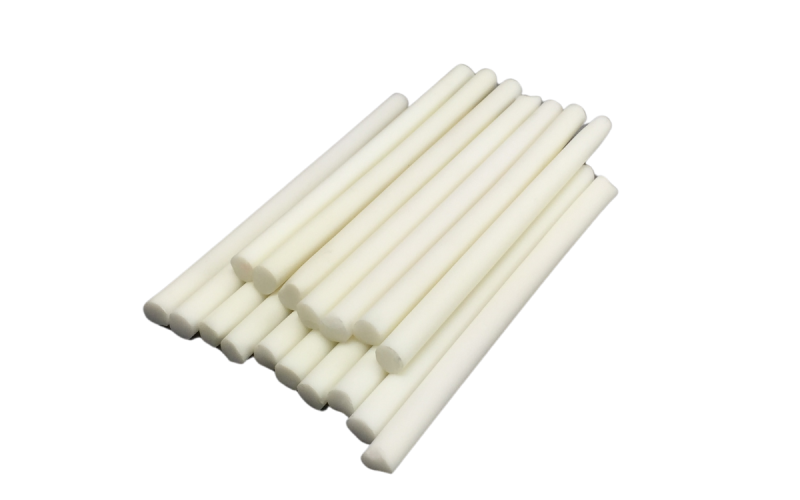

At Eshino Precision, we’re experts at machining alumina ceramic into parts like alumina rods. Let’s explore what it is, why it’s hard to machine, and how we do it in this easy guide, perfect for anyone curious about this amazing material.

Introduction: What’s Alumina Ceramic and Why It Matters

Alumina ceramic is a super-strong material made from aluminum oxide, or Al2O3. It’s not like the clay plates you eat off of! Instead, it’s a high-tech material used in cool things like smartphones, airplanes, and even hip replacements. Machining alumina ceramic means shaping it into exact parts, which is tricky but super important.

What Makes Alumina Special?

Alumina ceramic is awesome because it’s super hard, can handle crazy heat, and doesn’t wear out easily. For example, it’s used in electronics for insulators that keep circuits safe. It’s also safe for the body, so doctors use it in medical implants. At Eshino Precision, we love how versatile it is!

Why Do We Machine It?

Machining alumina ceramic turns it into precise parts like rods for furnaces or bearings for planes. It’s a big deal because industries need these parts to work perfectly. Dr. Emily Chen, a ceramics expert, says, “Machining alumina ceramic is critical for creating high-performance components that drive modern technology.” That’s why we’re so passionate about it!

A Huge Market

Here’s a fun fact: the alumina ceramics market is worth USD 43.57 billion in 2025 and keeps growing! It’s a big part of the advanced ceramics world, used in everything from aerospace to semiconductors. Our blog has more on why this material is taking over!

Alumina Ceramic Rod for Furnaces

Alumina Insulator for Electronics

Why Is Machining Alumina Ceramic So Tricky?

Machining alumina ceramic is like trying to carve a super-hard rock with a butter knife—it’s tough! Alumina is one of the hardest materials out there, and it has some quirks that make it hard to shape. Let’s break down why machining alumina ceramic is such a challenge.

It’s Super Hard

Alumina ceramic is almost as hard as a diamond, scoring a 9 on the Mohs scale. This means regular tools, like steel or carbide, just can’t cut it—they wear out super fast. Instead, we use special diamond tools to machine alumina ceramic, but even those need extra care.

It Can Crack Easily

Another problem is that alumina is brittle, like glass. If you push too hard or move too fast while machining alumina ceramic, it can crack or chip. This is a big deal for parts like CNC machine components that need to be perfect. We use slow, careful techniques to keep it safe.

It Costs More

Machining alumina ceramic is also expensive. Diamond tools and high-tech machines, like CNC systems, cost a lot. Plus, the process is slow to avoid mistakes, which adds to the time and price. But because alumina lasts so long, it’s worth it for things like wear-resistant parts.

How We Machine Alumina Ceramic

Even though machining alumina ceramic is tough, we’ve got some awesome ways to do it! At Eshino Precision, we use special techniques to shape alumina into perfect parts. Here’s how we make it happen.

Diamond Grinding

Diamond grinding is like using super-strong sandpaper. We use wheels covered in diamond bits to slowly smooth out alumina ceramic. It’s great for flat surfaces or round parts like alumina rods. This method is super precise, but it takes time and lots of water to keep things cool.

Laser Machining

Laser machining is like using a sci-fi beam! A laser cuts alumina ceramic quickly, especially for thin or fancy shapes like circuit boards. But the heat can sometimes cause tiny cracks, so we’re extra careful. It’s a fast way to machine alumina ceramic for complex designs.

Ultrasonic Machining

Ultrasonic machining uses tiny vibrations and a gritty liquid to shape alumina ceramic. It’s perfect for making small holes or detailed parts without breaking them. This method is slower but super safe for delicate stuff like medical components. We love how gentle it is!

Which Method Is Best?

Here’s a table to compare these methods for machining alumina ceramic:

| Method | Precision | Speed | Best For |

|---|---|---|---|

| Diamond Grinding | High | Slow | Rods, flat surfaces |

| Laser Machining | Medium | Fast | Complex shapes |

| Ultrasonic Machining | High | Slow | Small holes, delicate parts |

Tools and Machines We Use

Machining alumina ceramic needs some seriously cool tools and machines because it’s so hard! At Eshino Precision, we use the best equipment to shape alumina into perfect parts. Let’s check out what we use to make machining alumina ceramic work like magic.

Diamond Tools: The Tough Guys

Since alumina ceramic is super hard, only diamond tools can handle it. These tools are like the superheroes of machining! We use: – Diamond Grinding Wheels: For smoothing flat surfaces or alumina rods. – Diamond Drills: To make tiny holes in parts like electronic insulators. – Diamond Cutters: For shaping or trimming alumina ceramic. These tools are pricey, but they’re the only way to machine alumina ceramic without breaking everything! Learn more about our CNC machining process.

CNC Machines: Smart Robots

We also use CNC machines, which are like super-smart robots. They control the diamond tools to cut alumina ceramic exactly how we want. CNC stands for Computer Numerical Control, and it makes sure every part is perfect, whether it’s for aerospace or medical uses. Dr. Emily Chen, a ceramics expert, says, “CNC machines are game-changers for machining alumina ceramic with precision.”

Coolants: Keeping Things Chill

Machining alumina ceramic makes things hot! So, we use special liquids called coolants, like water or oils, to keep the tools and alumina cool. This stops cracks and helps tools last longer. For example, when we grind alumina rods, we pour on lots of coolant to keep everything safe.

Our Equipment Lineup

Here’s what we use to machine alumina ceramic: – CNC grinding machines for super-precise cuts. – Laser systems for fast, fancy shapes. – Ultrasonic setups for tiny, delicate parts. – Lots of diamond tools for every job. Check out our custom components guide to see how we use these tools!

Best Tips for Machining Alumina Ceramic

Machining alumina ceramic is tricky, but we’ve got some awesome tips to do it right! At Eshino Precision, we follow these steps to make sure every part is perfect, from alumina rods to tiny semiconductor parts. Here’s how we do it.

Go Slow and Steady

When machining alumina ceramic, we set our machines to go slow and gentle. This means using low speeds and small cuts to avoid cracking the material. For example, when we grind machine parts, we take our time to get it just right. Slow and steady wins the race!

Use Lots of Coolant

Coolant is super important! It keeps the alumina ceramic and tools from getting too hot, which could cause cracks. We always use a big flow of water or special liquids, especially during high-temperature grinding. This trick helps us make smooth, strong parts.

Hold It Tight

Alumina ceramic can wiggle during machining, which is bad news—it might chip! So, we use special holders to keep it super still. These holders are designed for ceramics, so our CNC machine parts come out perfect every time.

Check Everything Often

Real Examples from Eshino Precision

At Eshino Precision, we’ve machined alumina ceramic for some really cool projects! These real examples show how machining alumina ceramic helps make awesome things. Let’s take a look at a few.

Electronics: Insulators for Chips

In electronics, we machine alumina ceramic into insulators for semiconductor chips. These insulators keep electricity where it belongs, making your phone or computer work smoothly. We use CNC machines to get super-precise shapes for 5G equipment.

Medical: Hip Replacements

For medical uses, we machine alumina ceramic into parts for hip replacements. Alumina is safe for the body and super strong, so these parts last a long time. Our alumina components are polished to be super smooth, helping patients move better.

Aerospace: Tough Bearings

In aerospace, we make alumina ceramic bearings that handle high speeds and heat. These bearings are light but strong, perfect for planes. We use high-strength alumina to ensure they last in tough conditions. Check out our high-strength ceramics guide for more!

The Growing Market for Alumina Ceramic

The world is going crazy for alumina ceramic, and machining alumina ceramic is a big part of that! This super-strong material is in high demand because it’s used in so many cool industries. Let’s look at why the market is growing and what it means for machining alumina ceramic in 2025.

A Huge and Growing Market

In 2025, the alumina ceramics market is worth a whopping USD 43.57 billion! That’s a big chunk of the advanced ceramics market, which is around USD 124.48 billion. Experts say the alumina market will grow by 10.3% every year until 2034, reaching USD 105.28 billion. Plus, the machines used for machining alumina ceramic are part of a market expected to hit USD 9.5 billion by 2033. That’s a lot of growth! Check out our blog for more market insights.

Market Data Table

Here’s a quick table to show the numbers:

| Market | Size (2025) | Projected Size | Growth Rate |

|---|---|---|---|

| Alumina Ceramics | USD 43.57 billion | USD 105.28 billion (2034) | 10.3% |

| Ceramic Machinery | USD 5.9 billion | USD 9.5 billion (2033) | 5.4% |

Why Is It Growing?

So, why is machining alumina ceramic so popular? Industries like electronics, healthcare, and aerospace need alumina for things like 5G equipment, implants, and jet engine parts. Alumina’s heat resistance and durability make it perfect. Dr. Emily Chen notes, “The demand for machined alumina parts is soaring as industries push for more efficient, long-lasting components.”

What It Means for You

This growth means more companies need expert machining for alumina ceramic. At Eshino Precision, we’re ready to help with custom parts for any industry. Whether it’s semiconductor insulators or furnace rods, we’ve got you covered!

What’s Next for Machining Alumina Ceramic

The future of machining alumina ceramic is super exciting! New technology and ideas are making it easier, faster, and better. At Eshino Precision, we’re always looking for ways to improve how we machine alumina ceramic. Let’s see what’s coming up!

Smarter CNC Machines

New CNC machines are like brainy robots! They have better controls to machine alumina ceramic faster and with fewer mistakes. This means we can make parts like CNC rods even more precise for aerospace or medical uses.

Hybrid Machining Tricks

Hybrid machining is a cool new idea where we mix methods like laser and ultrasonic machining. This makes machining alumina ceramic more efficient because it reduces tool wear and gets better results. It’s like teamwork for machines! We’re testing this for complex parts in electronics.

3D Printing and Machining

3D printing is changing things by letting us “print” rough alumina shapes. But for super-precise parts, machining alumina ceramic is still key. For example, we might 3D print a part and then grind it for semiconductor equipment. This combo saves time and money!

A Bright Future

With these new ideas, machining alumina ceramic will keep getting better. We’re excited to use them to make custom components for energy systems, implants, and more. Stay tuned to our blog for updates!

Common Questions Answered

People have lots of questions about machining alumina ceramic, and we’re here to help! These are the top questions we hear, answered in a way that’s super easy to understand. Let’s dive in!

How Do You Machine Alumina Ceramic?

Machining alumina ceramic uses special methods like diamond grinding, laser cutting, or ultrasonic machining. We use diamond tools and CNC machines to make sure parts like alumina rods are perfect.

What Tools Work Best?

Only diamond tools can handle machining alumina ceramic because it’s so hard! We use diamond grinding wheels, drills, and cutters. Regular tools like steel or carbide just wear out too fast. Learn more about our hard materials.

Can You Machine It After Firing?

Yes, but it’s tougher! After firing, alumina ceramic gets even harder, so we need extra-strong diamond tools and careful settings. This is common for aerospace parts that need super precision.

Conclusion: Why Choose Eshino Precision?

Machining alumina ceramic is a big challenge, but it’s worth it for the amazing parts it creates! From furnace rods to medical implants, alumina ceramic makes things stronger, lighter, and longer-lasting. At Eshino Precision, we use top-notch tools, like diamond grinders and CNC machines, to get it right every time. With the alumina market growing to USD 105.28 billion by 2034, now’s the time to jump in!

Ready to see how machining alumina ceramic can help your projects? Explore our alumina solutions or check out our custom components. Got a specific need? Contact us today to start creating awesome parts for aerospace, electronics, or more!

External Resources

Want to learn more? Here are some great places to dig deeper:

Ready to Transform Your Engineering Solutions?

No industrial challenge is too complex for Eshino. From precision ceramic rods and advanced bushings to customized nozzles and other high-performance components, we engineer solutions that combine exceptional durability, thermal resistance, and precision to meet your specific needs. Whatever your industry demands, Eshino delivers tailored expertise you can trust.