At Eshino, our chemical stability solutions are designed to combat the harshest chemical environments, ensuring your equipment and systems remain intact and operational. From aggressive acids to relentless saltwater exposure, our advanced materials deliver unmatched resistance to degradation, empowering industries like manufacturing, energy, and aerospace to perform at their best.

Tired of frequent repairs and unexpected failures due to chemical wear? Our solutions provide long-lasting protection, saving you time, money, and frustration.

Fortify your operations with top-tier chemical stability!

Chemical stability refers to a material’s ability to withstand chemical reactions that cause corrosion, erosion, or breakdown. Our offerings shine with:

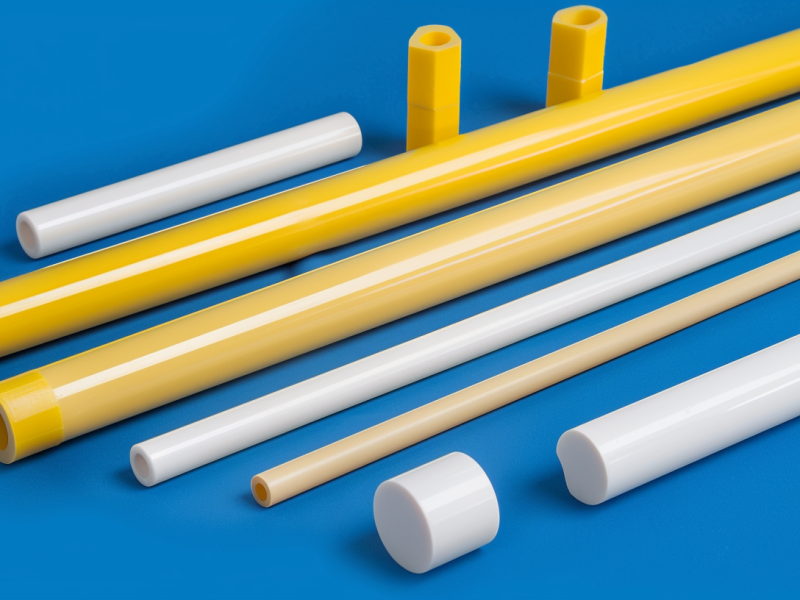

Unlike conventional materials that falter under chemical stress, our ceramics and engineered composites provide a dependable barrier, keeping your systems running smoothly.

Our chemical stability solutions deliver measurable value:

Say goodbye to chemical erosion and hello to operational excellence.

Our materials are trusted in demanding sectors:

Here’s how we stack up:

| Material | Chemical Resistance | Thermal Stability | Key Advantage |

|---|---|---|---|

| Advanced Ceramics | Exceptional | Outstanding | Longevity |

| Engineered Composites | Excellent | Very Good | Versatile |

| Titanium | Good | Excellent | High cost |

| Plastic | Moderate | Poor | Limited durability |

Graph: Performance of materials under prolonged chemical exposure.

Their non-reactive nature prevents degradation from corrosive substances.

Yes, our solutions are engineered for dual-threat environments.

Our materials resist uniform corrosion better and last longer.

We provide custom testing to match your exact conditions.

Does Your Project Need Chemical Stability Ceramics? Discover how our advanced ceramic rods can enhance your application. Ready to enhance your system’s resilience?

We will get back to you within 12 hours.