When your applications encounter drastic temperature changes, thermal shock resistance is the key to preventing cracks, failures, and costly interruptions. At Eshino, our cutting-edge ceramics are crafted to withstand rapid thermal cycling, delivering reliability and durability in even the toughest conditions. Whether it’s aerospace, industrial furnaces, or automotive systems, we’ve got you covered.

Struggling with component breakdowns, unpredictable downtime, or performance loss due to thermal shock? Our ceramics eliminate these frustrations, offering a robust solution you can trust.

Protect your systems from thermal shock damage!

Thermal shock resistance measures a material’s ability to endure sudden temperature fluctuations without fracturing. Our advanced ceramics stand out thanks to:

Unlike metals or glass, our ceramics thrive in environments with unpredictable temperature swings, ensuring consistent operation where other materials falter.

Our ceramics provide real-world advantages tailored to your needs:

Leave thermal shock concerns behind with a solution built for endurance.

Our ceramics are proven in demanding applications:

See how our ceramics stack up:

| Material | Thermal Shock Resistance | Key Benefit |

|---|---|---|

| Alumina (Al₂O₃) | Excellent | Robust and cost-effective |

| Zirconia (ZrO₂) | Very Good | Superior toughness |

| Silicon Carbide (SiC) | Outstanding | Unmatched thermal resilience |

| Glass | Poor | Brittle under thermal stress |

Graph: Ceramics vs. traditional materials in thermal shock scenarios.

Their low expansion and high strength outperform metals, resisting cracks effectively.

Silicon carbide (SiC) offers top-tier resistance for the harshest conditions.

Yes, our ceramics are designed for both high heat and sudden drops.

Definitely—our specialty is crafting solutions to match your requirements.

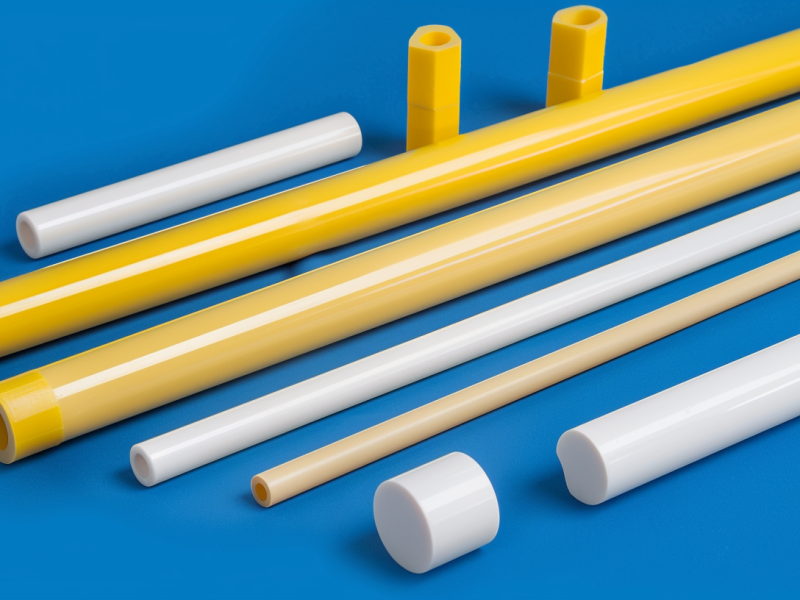

Does Your Project Need Thermal Shock Resistant Ceramics? Discover how our advanced ceramic rods can enhance your application. Ready to boost your application’s thermal stability?

We will get back to you within 12 hours.