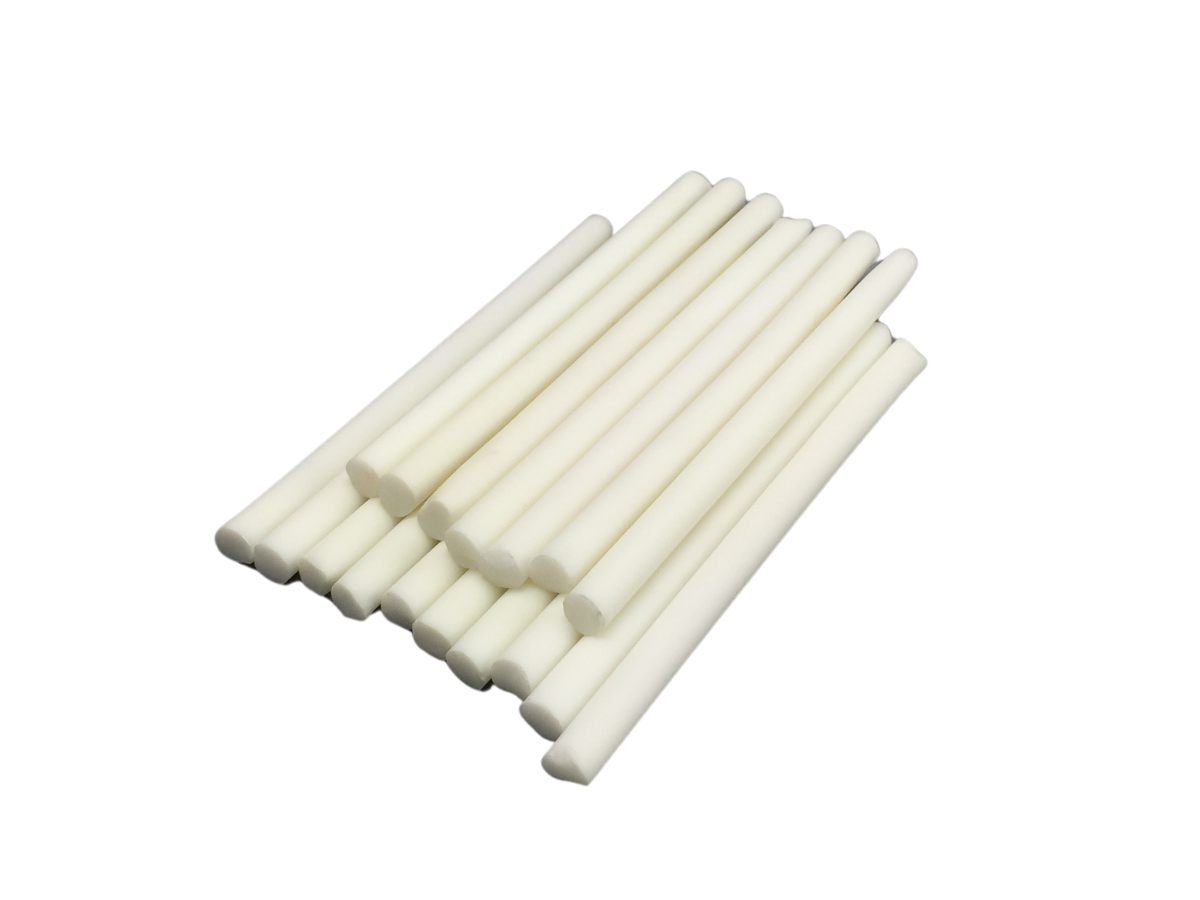

Unlock the potential of High-Performance Silicon Nitride Ceramic Rods – engineered for unmatched strength, durability, and reliability in the most demanding industries.

Silicon nitride is a high-performance ceramic material that combines excellent strength, thermal stability, and wear resistance. It is one of the most durable and versatile ceramic materials available, making it ideal for use in demanding applications, including automotive, aerospace, and industrial manufacturing.

Silicon nitride (Si₃N₄) ceramic rods are known for their exceptional mechanical, thermal, and chemical properties. These rods are used in a wide range of applications, particularly in high-performance industries where durability, high strength, and resistance to extreme conditions are crucial. Below is a comprehensive overview of silicon nitride ceramic rods and their key features.

Key benefits of silicon nitride ceramic rods:

Silicon nitride ceramics are known for their outstanding mechanical, thermal, and electrical properties, which make them suitable for high-demand applications. It is with excellent overall performance. Below is a summary of their key properties:

| Property | Value |

| Hardness | 1600–1800 HV (Vickers) |

| Flexural Strength | 600–1000 MPa |

| Thermal Conductivity | 20–30 W/m·K |

| Electrical Insulation | Excellent (non-conductive) |

| Wear Resistance | High (ideal for abrasive environments) |

| High-Temperature Resistance | Up to 1400°C |

| Corrosion Resistance | Excellent (resistant to many acids and alkalis) |

Silicon nitride ceramics are renowned for their exceptional mechanical strength and toughness. Unlike traditional ceramics, which are often brittle, silicon nitride exhibits high fracture toughness, allowing it to withstand significant mechanical loads without cracking or chipping. This property is particularly crucial in applications such as turbine blades and engine components, where reliability under stress is paramount. The compressive strength of silicon nitride ceramics can reach up to 2500 MPa, and they maintain high performance over a broad temperature range due to their high melting point and thermal stability.

One of the standout features of silicon nitride ceramics is their thermal stability. These materials are capable of enduring extreme temperatures, which makes them ideal for high-temperature engineering applications. Silicon nitride demonstrates good thermal shock resistance, allowing it to withstand rapid changes in temperature without fracturing. This property is particularly beneficial in sectors such as aerospace and automotive, where components are exposed to fluctuating thermal conditions.

Silicon nitride ceramics are chemically inert and resistant to corrosion, which makes them suitable for use in hostile environments. Their resistance to chemical attack is particularly advantageous in industries like biomedicine and electronics, where materials must endure exposure to various chemicals without degrading.

The wear and abrasion resistance of silicon nitride ceramics is another important property. These materials are designed to withstand wear in high-stress applications, making them ideal for components like bearings and seals, which require durability and longevity under frictional conditions. This exceptional wear resistance is a key reason why silicon nitride ceramics are increasingly used in automotive and industrial machinery applications.

Additionally, silicon nitride ceramics possess good electrical insulation properties, making them suitable for electronic applications. They can be utilized in high-voltage environments where electrical conductivity could pose safety risks or operational challenges.

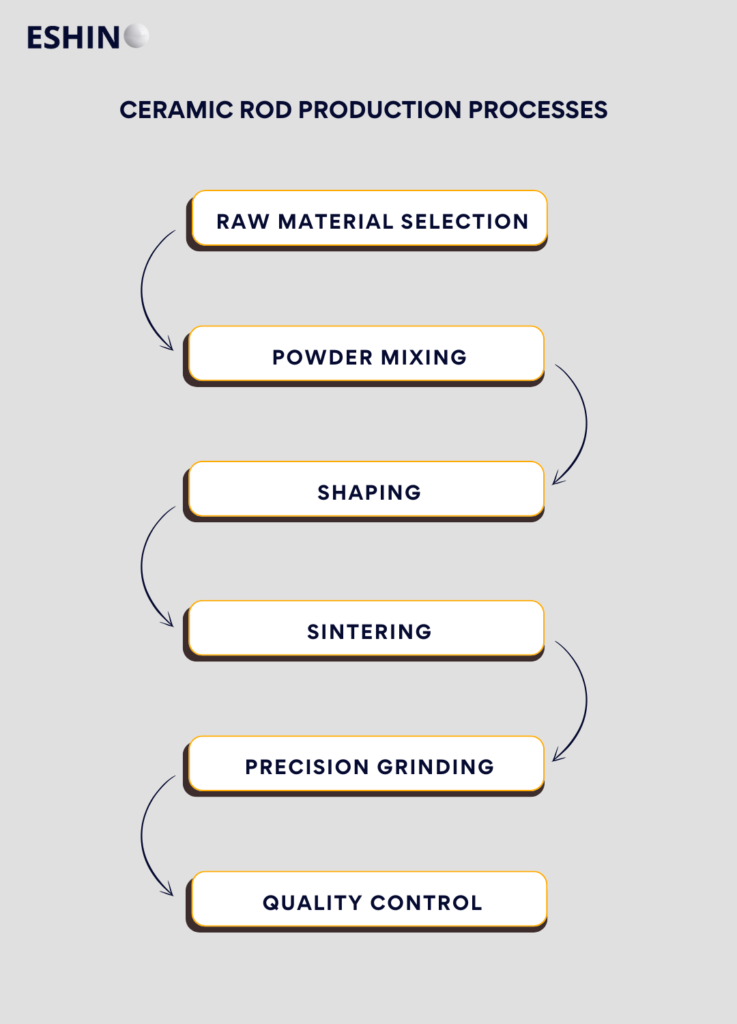

The production of silicon nitride ceramic rods involves several important steps to ensure their performance and reliability:

High-purity silicon nitride powder is selected for its superior mechanical and thermal properties.

The powder is mixed with binders and solvents to create a uniform slurry that can be easily shaped.

The slurry is shaped into rods using methods such as extrusion, molding, or casting.

The formed rods are fired at high temperatures (1600°C – 1700°C) in a controlled atmosphere to achieve high density and strength.

After sintering, the rods are precision-ground to ensure accurate dimensions and smooth surfaces.

The final product is subjected to rigorous testing for mechanical strength, thermal stability, and other key properties to ensure it meets performance standards.

This multi-step process guarantees that silicon nitride ceramic rods maintain their exceptional durability, high strength, and precision, making them suitable for the most demanding applications.

Silicon nitride ceramic rods are increasingly utilized across a diverse range of industries due to their superior mechanical properties, thermal stability, and lightweight characteristics. Their applications span several sectors, including aerospace, automotive, and biomedical, each benefiting from the unique properties of this advanced material. Below are some of the most common applications:

Silicon nitride ceramic rods offer several key advantages that make them stand out in various applications:

Silicon nitride ceramic rods offer unparalleled performance in a wide range of industries, including aerospace, automotive, medical, energy, and semiconductor industries. Their high strength, wear resistance, thermal stability, and corrosion resistance make them the material of choice for critical components in advanced technology applications.

Click the following button to talk with our technical expert totailor-made your ceramic rods for your application.

For any customized requests, talk with us now!

We’re here 24/7/365, ensuring you get the best, always.

A client needed ceramic rods at 550mm with a 0.1 straightness, a task many deemed impossible. Using advanced techniques and teamwork, we not only met the specs but set a new industry standard. Now, 700mm rods are routine for us, proving our unmatched expertise in advanced ceramics.

Contact us now to customize your long ceramic rods.

We will get back to you within 12 hours.