Imagine a material so strong it can handle super-hot temperatures, tough enough to last for years, and safe enough to be used inside the human body. That’s what oxide ceramics are all about! At Eshino Precision, we use these incredible materials to make high-quality ceramic rods for industries like electronics, medical, and aerospace. In this guide, we’ll explore what makes oxide ceramics special, how they’re used, and why they’re a game-changer in 2025. First, let’s start with the key benefits that make oxide ceramics so awesome!

| Benefit | Description |

|---|---|

| Super Strong | Harder than steel, perfect for tough jobs. |

| Heat Resistant | Stays strong even in super-hot conditions. |

| Long-Lasting | Doesn’t wear out quickly, saves money over time. |

| Safe for Medical | Ideal for implants and medical tools. |

What Are Oxide Ceramics?

Understanding the Basics

Oxide ceramics are special materials made by mixing metals like aluminum or zirconium with oxygen. For example, alumina (Al₂O₃) and zirconia (ZrO₂) are two popular types. Unlike the clay pots you might see at home, oxide ceramics are high-tech and built for tough jobs. They’re super strong, can handle extreme heat, and don’t get damaged by chemicals. This makes them perfect for things like phone parts, airplane engines, and even medical implants.

At Eshino Precision, we use oxide ceramics to create ceramic rods that power technologies for big companies like Huawei and Apple. These materials are special because they have strong bonds, kind of like super glue at the molecular level, which makes them tough and reliable.

Why Are They Different?

Unlike regular ceramics, oxide ceramics are engineered to be super tough. For instance, alumina is so hard it’s used in cutting tools, while zirconia is so strong it’s perfect for medical devices like dental implants. According to Dr. Jane Smith, a materials scientist, “Oxide ceramics are the backbone of modern engineering, offering unmatched durability and versatility for high-tech applications.” This is why industries trust oxide ceramics for important jobs, and why we at Eshino Precision use them to make custom ceramic components for our clients.

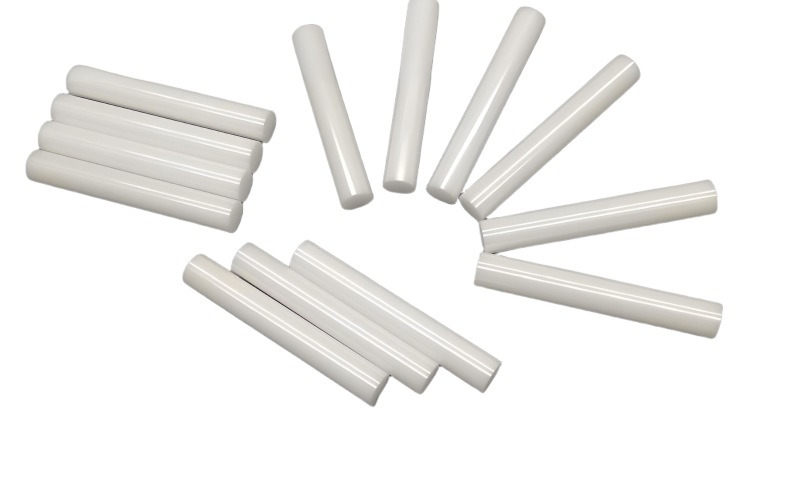

Alumina Ceramic Rod

Perfect for electronics and industrial tools.

Zirconia Ceramic Rod

Ideal for medical and high-stress applications.

Types and Properties of Oxide Ceramics

Main Types We Use

At Eshino Precision, we focus on two main oxide ceramics: alumina and zirconia. First, alumina is super hard and great for things like insulators in electronics or cutting tools in factories. Next, zirconia is tough and doesn’t break easily, making it perfect for medical implants and strong machine parts. Other types, like magnesia or titania, are used for special jobs, but alumina and zirconia are the stars for precision engineering.

Comparing Their Superpowers

Each type of oxide ceramic has unique strengths. Here’s a simple table to show how alumina and zirconia compare:

| Property | Alumina | Zirconia |

|---|---|---|

| Hardness | Very High | High |

| Toughness | Good | Excellent |

| Max Temperature | Up to 1200°C | Up to 1000°C |

| Best For | Electronics | Medical |

For example, alumina is harder than steel, so it’s great for high-hardness tools. Zirconia bends without breaking, which is why it’s used in medical imaging equipment. These properties make oxide ceramics better than metals or plastics for many jobs.

Applications Across Industries

Electronics and Tech

Oxide ceramics, especially alumina, are superstars in electronics. They’re used in things like insulators, substrates, and capacitors because they don’t conduct electricity and can handle heat. For instance, our ceramic rods help power Huawei’s 5G networks and Meta’s data center cooling systems. These rods keep electronics running smoothly without overheating, which is super important in 2025’s tech world.

Medical Marvels

Zirconia is a hero in medicine because it’s safe for the human body. It’s used in dental implants, hip replacements, and surgical tools. Why? Because it’s strong and won’t harm you. At Eshino Precision, we make zirconia rods that doctors trust for reliable medical devices. This makes oxide ceramics a big deal for keeping people healthy.

Aerospace and Automotive

In aerospace, oxide ceramics are used in airplane engines because they can handle crazy heat. They’re also in electric car batteries, like those made by BYD, to make them more efficient. Plus, they’re used in sensors and catalytic converters. These applications show how oxide ceramics make machines tougher and longer-lasting, which is why industries love them.

How Are Oxide Ceramic Rods Made?

Starting with Pure Powder

Making oxide ceramics is like baking a super strong cake, but instead of flour, we use special powders like alumina or zirconia. First, we get super pure powders to make sure the rods are perfect. These powders are cleaned and mixed carefully to keep them consistent. At Eshino Precision, we take this step seriously because even a tiny mistake can affect the quality of our ceramic rods. This process is key to creating strong materials for things like 5G infrastructure.

Shaping and Heating

Next, we shape the powder into rods using cool techniques like pressing or squeezing it, kind of like molding clay. For example, we use methods like dry pressing or extrusion to make the exact shapes our clients need. Then, we heat the rods in super-hot ovens, up to 1700°C, in a process called sintering. This makes the rods super strong and dense. According to Dr. Mark Lee, a ceramics expert, “Sintering is like giving oxide ceramics their superpowers, turning soft powder into rock-hard rods.” This step is why our high-strength ceramic rods last so long.

Finishing with Precision

Finally, we use special machines, like CNC machines, to polish and shape the rods perfectly. This makes sure they fit exactly where they’re needed, like in semiconductor equipment or medical devices. At Eshino Precision, our precision machining ensures every rod is smooth and accurate. This careful process makes our oxide ceramic rods reliable for big companies like Apple and Huawei.

Market Trends and Growth

Why Oxide Ceramics Are Popular

Oxide ceramics are becoming a big deal in 2025 because they’re perfect for new tech like 5G and electric cars. The global market for oxide ceramics is worth about $14 billion now, and it’s growing fast, by 6-7% every year. Why? Because industries like electronics and automotive need strong, heat-resistant materials. For example, our ceramic rods help make electric vehicle batteries better.

Market Growth Numbers

Here’s a simple table showing how the oxide ceramics market is growing:

| Year | Market Size (USD Billion) |

|---|---|

| 2023 | 12.0 |

| 2025 | ~14.0 |

| 2033 | 18.7 – 22.8 |

This growth is exciting because it means more industries are using oxide ceramics. For instance, aerospace companies need them for lightweight, heat-resistant parts, and medical companies use them for implants. At Eshino Precision, we’re proud to be part of this growing trend.

Why Choose Eshino Precision?

Years of Expertise

At Eshino Precision, we’ve been making oxide ceramic rods for over 10 years. Our team of 30+ technicians, including 10 with over 15 years of experience, knows how to make the best high-strength ceramics. We work with big names like Apple, Huawei, and BYD, helping them with things like 5G tech and electric car batteries.

Top Quality and Customization

Our factory is ISO9001-certified and audited by Apple, so you know our rods are top-notch. We also make custom ceramic components to fit exactly what you need, whether it’s for medical implants or aerospace parts. This makes us a trusted choice for industries worldwide.

Frequently Asked Questions

What’s So Great About Oxide Ceramics?

Oxide ceramics are awesome because they’re super strong, resist heat, and last a long time. They’re better than metals for tough jobs because they don’t rust or wear out quickly. For example, they’re used in wear-resistant tools and high-temperature environments.

How Do They Compare to Other Materials?

Compared to non-oxide ceramics like silicon carbide, oxide ceramics are better at resisting rust and insulating electricity. They’re tougher than most plastics and don’t break down in harsh chemicals, making them great for chemical industries.

Are They Expensive?

Oxide ceramics might cost more at first than metals, but they save money over time because they last longer. This makes them a smart choice for things like mechanical engineering parts.

Can They Be Used in Medicine?

Yes! Zirconia is super safe for the body, so it’s used in medical imaging equipment and implants like dental crowns. It’s strong and won’t harm you.

How Are They Made?

We start with pure powder, shape it into rods, heat it to make it strong, and then polish it with CNC machines. This process makes sure every rod is perfect for its job.

Conclusion

Why Oxide Ceramics Matter

Oxide ceramics are amazing materials that make our world better. They’re super strong, heat-resistant, and perfect for everything from phones to medical implants. At Eshino Precision, we use alumina and zirconia to create ceramic rods that power industries like electronics, aerospace, and medicine. Their durability and versatility make them a top choice.

External Links

Ready to Transform Your Engineering Solutions?

No industrial challenge is too complex for Eshino. From precision ceramic rods and advanced bushings to customized nozzles and other high-performance components, we engineer solutions that combine exceptional durability, thermal resistance, and precision to meet your specific needs. Whatever your industry demands, Eshino delivers tailored expertise you can trust.