The ultimate rods for abrasive, chemical, and high-temperature environments.

Silicon carbide (SiC) rods are advanced ceramic components designed for the harshest conditions. They are extremely hard, chemically inert, and thermally stable, making them perfect for pumps, seals, bearings, and furnace applications.

SiC stands out for its extreme wear resistance and corrosion resistance, outperforming almost all other materials when both abrasion and chemicals are present.

| Parameter | Typical Value | Notes |

|---|---|---|

| Material | Silicon Carbide (SiC) | Sintered / reaction-bonded grades |

| Color | Gray / Black | Sleek industrial look |

| Density | ~3.07–3.15 g/cm³ | Lightweight vs metals |

| Flexural Strength | ~400–500 MPa | Strong for load-bearing |

| Fracture Toughness | ~4 MPa·m½ | Moderate |

| Hardness | 22–28 GPa | Extreme wear resistance |

| Max Temperature | ~1400–1600 °C | Atmosphere dependent |

| Thermal Conductivity | ~120–200 W/m·K | Excellent for heat dissipation |

| Thermal Expansion | ~3.6–4.1 ×10⁻⁶/K | Very stable under cycling |

| Electrical Properties | Semi-conductive | Not ideal as insulator |

| Diameter Range | 3–80 mm | Customizable |

| Length Range | Up to 1000 mm | Long rods available |

| Surface Finish | Polished / Ground | Precision finish |

| Tolerances | ±0.01–0.05 mm | Tight tolerance achievable |

| MOQ | 1 piece | Prototype friendly |

Alumina Rods – high-temperature & insulating

Zirconia Rods – toughness & impact resistance

Silicon Nitride Rods – thermal shock resistance & lightweight

Silicon Carbide Rods – featured here: extreme wear + chemical resistance

| Property | Advantage for You |

|---|---|

| Extreme Hardness & Wear Resistance | With Mohs hardness ~9.5, SiC rods resist abrasion and friction, lasting far longer in sliding or rotating use. |

| High-Temperature Stability | Operates reliably at ~1400–1600 °C, depending on grade and atmosphere. |

| Outstanding Corrosion Resistance | Inert in most acids, alkalis, and solvents — where metals and plastics fail. |

| High Thermal Conductivity | Dissipates heat quickly, preventing hot spots and thermal buildup. |

| Low Thermal Expansion | Maintains dimensional stability across temperature cycles. |

| Lightweight vs Metals | Density ~3.1 g/cm³ makes them lighter while still being stronger than metals in harsh conditions. |

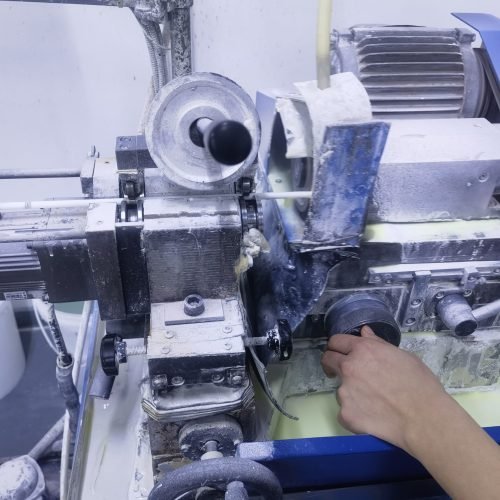

Pump shafts & plungers – slurry, wastewater, chemical pumps

Mechanical seals – extreme wear/corrosion resistance under sliding contact

Bearings & bushings – long-lasting rods in abrasive or corrosive fluids

Furnace rods & supports – reliable at >1400 °C

Nozzles, spray rods, hot gas components – where heat + abrasion meet

Semiconductor & electronics tools – rods with thermal conductivity + stability

| Property / Problem | Metal Rods | Plastic/Resin Rods | Glass Rods | SiC Rods |

|---|---|---|---|---|

| Wear Resistance | ⚠ Moderate | ❌ Weak | ⚠ Brittle | ✅ Extreme, best among ceramics |

| Corrosion Resistance | ❌ Rusts | ⚠ Limited | ⚠ Poor | ✅ Excellent, even in acids/alkalis |

| High Temp Resistance | ⚠ ~600 °C | ❌ ~250 °C | ⚠ Fails | ✅ ~1400–1600 °C |

| Toughness | ✅ Strong but corrodes | ⚠ Weak | ❌ Brittle | ⚠ Moderate (not as tough as ZrO₂) |

| Electrical Insulation | ❌ Conductive | ⚠ Partial | ⚠ Partial | ⚠ Semi-conductive in some grades |

| Lifetime & Cost | ⚠ Frequent replacements | ⚠ Short life | ⚠ Fragile | ✅ Longest life, lowest total cost |

Metal rods rust, corrode, and wear quickly in abrasive or chemical environments.

Plastic rods soften, deform, and fail under heat or friction.

Glass rods are fragile and break under vibration or thermal stress.

👉 If your application requires maximum wear resistance, chemical stability, and high-temperature strength, Silicon Carbide (SiC) Ceramic Rods are the best choice.

| Feature / Property | Alumina (Al₂O₃) | Zirconia (ZrO₂) | Silicon Nitride (Si₃N₄) | Silicon Carbide (SiC) |

|---|---|---|---|---|

| Max Temperature | ✅ ~1550 °C | ⚠ ~1000 °C | ✅ ~1100 °C | ✅ ~1400–1600 °C |

| Toughness | ⚠ Moderate | ✅ Very High | ✅ Good | ⚠ Moderate |

| Wear Resistance | ✅ Good | ✅ Excellent | ✅ High | ✅ Extreme |

| Density | Medium (~3.9 g/cm³) | Heavy (~6.0 g/cm³) | Light (~3.2 g/cm³) | Medium (~3.1 g/cm³) |

| Thermal Shock Resistance | ⚠ Moderate | ✅ Good | ✅ Excellent | ⚠ Moderate |

| Electrical Insulation | ✅ Excellent | ✅ Excellent | ✅ Good | ⚠ Semi-conductive |

| Best Fit Use | High heat, insulation | Impact/vibration | Thermal cycles, dynamic loads | Abrasive, corrosive, hot environments |

Background:

A U.S. chemical equipment manufacturer used metal rods in acid-handling pumps that corroded in months.

Solution:

They switched to SiC rods for plungers.

Results:

Lifetime increased from 3 months → 18+ months

Reduced maintenance costs by 65%

Stable performance in strong acids

Background:

Operators struggled with abrasive slurry wearing down steel rods in pumps.

Solution:

Replaced with SiC rods precision-polished for low friction.

Results:

Service life extended 5× longer

Pump downtime reduced significantly

Consistent performance despite abrasive solids

Powder → Forming → Sintering → CNC/Grinding → Inspection → Packaging → Delivery

Up to ~1600 °C, depending on grade and atmosphere.

They are very hard but less tough than zirconia — not ideal for impact loads.

Do SiC rods conduct electricity?

Some grades are semi-conductive; not all are perfect insulators.

Pumps, seals, furnaces, bearings, and any abrasive/corrosive/high-temp environment.

MOQ is 1 piece; prototypes usually 3–4 weeks, production orders longer.

20+ Years Ceramic Expertise – trusted by Apple, BYD, Huawei, and global leaders

Advanced Production – ISO9001 certified, SOP-controlled, and Apple-audited factory

Fast Lead Time – over 95% on-time delivery, higher than industry average

Custom Solutions – small MOQ (from 1 piece) to mass production, tailored to your design

Full Technical Support – our ceramic engineers help you choose the right grade and design

We will get back to you within 12 hours.