| Feature | Details |

|---|---|

| Material | Silicon carbide, as hard as a diamond! |

| Max Temperature | Up to 1650°C – hotter than lava! |

| Best For | Harsh places like chemical plants or furnaces |

| Market Growth | Heat exchanger market: $688M in 2023, growing 8.2% yearly |

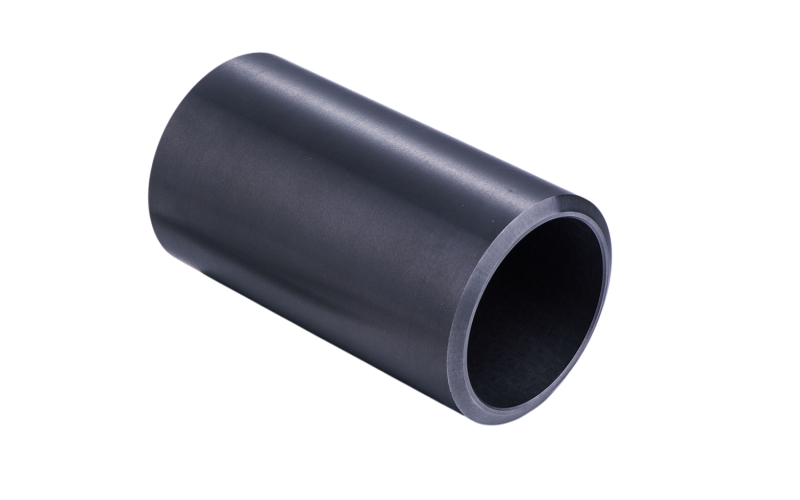

Hey there! Imagine a super tough tube that can handle crazy heat and harsh chemicals without breaking. That’s what silicon carbide tubes are all about! At Eshino Precision, we make these amazing ceramic parts for all kinds of industries. So, let’s dive into why silicon carbide tubes are so cool and how they help make things like power plants and spaceships work better.

Introduction to Silicon Carbide Tubes

Why Silicon Carbide Tubes Matter

Silicon carbide tubes are like superheroes in the world of ceramics. They’re made from a special material called silicon carbide, which is crazy strong. These tubes can handle super hot temperatures and tough conditions. For example, they’re used in places like chemical plants or power stations. At Eshino Precision, we’re experts at making these tubes with super precision, down to ±0.001mm! That’s thinner than a hair!

Why should you care? Well, silicon carbide tubes last longer than metal ones and don’t need fixing all the time. Plus, they’re getting more popular. The market for silicon carbide heat exchangers was worth $688 million in 2023 and is growing fast. By 2030, it could hit $1,179.4 million! That’s a big deal for industries needing tough parts.

Eshino Precision’s Role

At Eshino Precision, we’ve been making high-quality ceramic parts for years. Our silicon carbide tubes are used in cool stuff like electric cars and 5G networks. We use advanced machines to make sure every tube is perfect. Want to learn more about ceramics? Check out our guide on engineering ceramics.

“Silicon carbide tubes are game-changers for industries needing durability,” says Dr. Emily Chen, a materials scientist at TechCeramics Inc. “Their ability to withstand extreme conditions makes them essential for modern engineering.”

What You’ll Learn

In this guide, we’ll explain what silicon carbide tubes are and why they’re awesome. We’ll also cover where they’re used, how to pick the right one, and how they’re made. Plus, we’ll share some fun facts about their growing market. Let’s get started!

What Are Silicon Carbide Tubes?

The Basics of Silicon Carbide

Silicon carbide is a special ceramic that’s almost as hard as a diamond. It’s made by mixing silicon and carbon in a super hot oven. The result? A material that’s tough, lightweight, and perfect for making tubes. These silicon carbide tubes are used in places where things get really hot or super corrosive, like in chemical factories.

At Eshino Precision, we make these tubes with care. They’re part of our family of advanced ceramics, which also includes stuff like zirconia and alumina.

Why They’re Special

Silicon carbide tubes can handle temperatures up to 1650°C. That’s hotter than most ovens! They also don’t get damaged by acids or other harsh chemicals. This makes them perfect for tough jobs where metal tubes would break or rust. Want to compare ceramics? See our guide on silicon carbide vs. silicon nitride.

Where You’ll Find Them

You’ll see silicon carbide tubes in all sorts of cool places. For example, they’re used in power plants to protect sensors. They’re also in spaceships and even electric cars! Because they’re so strong, they’re a big part of industries like aerospace and automotive. Our team at Eshino Precision makes sure every tube is super precise for these important jobs.

Properties and Advantages of Silicon Carbide Tubes

Super Cool Features

Silicon carbide tubes have some amazing powers. Here’s a quick list of what makes them special:

- Super Hard: Almost as tough as a diamond, so they don’t wear out easily.

- Great Heat Conductor: Moves heat super well, about 120 W/mK.

- Stays in Shape: Doesn’t stretch or shrink when it gets hot or cold.

- Acid-Proof: Harsh chemicals can’t hurt them.

- Handles Heat: Works fine up to 1650°C!

- Slippery Surface: Reduces friction, so things move smoothly.

Learn more about these traits in our ceramic properties guide.

Why These Features Help

Because silicon carbide tubes are so tough, they last way longer than metal tubes. This saves money since you don’t need to replace them often. They also keep machines running smoothly in super hot or harsh places. For example, in a chemical plant, these tubes can handle acid without breaking. That’s why they’re perfect for chemical applications.

Real-World Benefits

Using silicon carbide tubes means less fixing and more working. They’re also super reliable, which is great for industries like energy. Plus, they help machines work better because they don’t overheat. At Eshino Precision, we make sure our tubes are top-notch, so you get all these benefits. Curious about other ceramics? Check out our zirconia vs. alumina guide.

Applications of Silicon Carbide Tubes Across Industries

Where They’re Used

Silicon carbide tubes are like all-stars in tons of industries. They’re super versatile because they’re so strong and heat-resistant. Here are some places you’ll find them:

- Chemical Plants: They’re in heat exchangers and tubes that carry harsh liquids.

- Power Plants: They protect sensors and support parts in super hot areas.

- Metal Factories: Used in furnaces to melt metals like aluminum.

- Spaceships: Help make engine parts that handle crazy heat.

- Electric Cars: Used in tough parts for batteries and motors.

- Labs: Found in science gear that needs to be super precise.

Want to know more? See our blog on SiC in aerospace.

Why They’re Perfect for These Jobs

These tubes are awesome because they don’t break under pressure. In chemical plants, they handle acids without a scratch. In power plants, they stay strong in super hot spots. This makes them a top pick for tough jobs. At Eshino Precision, we make sure our tubes fit perfectly in these industries.

Eshino’s Expertise

We’ve been making silicon carbide tubes for years, and we know how to make them just right. Our tubes are used in cool stuff like semiconductors and electric vehicle batteries. We use fancy machines to get every detail perfect, so you can trust our products.

Types of Silicon Carbide Tubes: Sintered, Reaction-Bonded, Recrystallized

Different Kinds of Silicon Carbide Tubes

Silicon carbide tubes come in three main types. Each one is a bit different and good for specific jobs. They’re called recrystallized, sintered, and reaction-bonded silicon carbide tubes. Let’s break them down so you can understand what makes each one special. At Eshino Precision, we make all these types with super care!

Comparing the Types

Here’s a table that shows how these silicon carbide tubes are different. It’s like a cheat sheet to help you pick the right one!

| Feature | Recrystallized SiC | Sintered SiC | Reaction-Bonded SiC |

|---|---|---|---|

| Purity | 99.5% (super pure!) | 98% | Over 88% |

| Max Temp (°C) | 1650 | 1550 | 1300 |

| Strength (MPa) | 110 (flexural) | 400 (flexural) | 380 (flexural) |

| Porosity | Less than 15% | 2.5% | 0.1% (super tight!) |

Which Type is Best?

Recrystallized SiC is super pure, so it’s great for things like making computer chips where you don’t want any dirt. Sintered SiC is really strong, perfect for tough jobs like heat exchangers in chemical plants. Reaction-bonded SiC is awesome for protecting sensors in hot places because it’s super tight and doesn’t let stuff leak through. Want to learn more about tough ceramics? Check out our high-strength ceramics guide. At Eshino Precision, we can help you pick the perfect silicon carbide tube for your needs!

How to Choose the Right Silicon Carbide Tube for Your Application

Things to Think About

Choosing the right silicon carbide tube is like picking the best tool for a job. You need to think about a few things. First, how hot will it get? Some tubes can handle 1650°C, but others are good up to 1300°C. Next, do you need it to be super pure? Or maybe it needs to be extra strong? At Eshino Precision, we help you figure this out!

Matching the Tube to Your Needs

Here’s a quick guide to help you choose:

- Need it super pure? Go for recrystallized silicon carbide tubes. They’re great for semiconductor work.

- Need it super strong? Pick sintered silicon carbide tubes for heavy jobs like chemical plants.

- Hot but not too hot? Reaction-bonded tubes work well up to 1300°C, like for sensor protection.

- Harsh chemicals? All silicon carbide tubes are great at fighting corrosion. See our corrosion resistance guide.

Get Expert Help

Don’t worry if this sounds tricky. Our team at Eshino Precision makes tubes with super precision, down to ±0.001mm. That’s crazy accurate! We can make custom silicon carbide tubes just for you. Want to know more about custom parts? Read our custom ceramic rods guide. “Choosing the right SiC tube can save you time and money,” says Dr. Emily Chen from TechCeramics Inc. “It’s all about matching the tube to your specific job.”

Manufacturing Process of Silicon Carbide Tubes

How They’re Made

Making silicon carbide tubes is like baking a super tough cake! First, we start with fine silicon carbide powder. This powder is mixed with special ingredients to make it strong. Then, we shape it into tubes using cool methods like squeezing it out or pressing it. At Eshino Precision, we’re pros at this!

Cooking the Tubes

After shaping, the tubes go into a super hot oven, between 2000°C and 2600°C. That’s way hotter than a regular oven! This process, called sintering, makes the tubes super strong and smooth. We do this in a special air-free room so they come out perfect. This helps silicon carbide tubes handle tough jobs like energy applications.

Why It Matters

This careful process makes sure every tube is super precise and tough. It’s why our silicon carbide tubes are used in things like spaceships and electric cars. Want to know more about how we make ceramics? Check out our ceramic injection molding guide. Our tubes are made to last, no matter how tough the job!

Market Trends and Statistics for Silicon Carbide Tubes

Growing Demand

Silicon carbide tubes are getting super popular! The market for silicon carbide heat exchangers was worth $688 million in 2023. Experts say it’ll grow to $1,179.4 million by 2030. That’s an 8.2% growth every year! This is because industries like chemical processing and power generation love how tough these tubes are.

Market Size Table

| Year | Market Size (US$ million) |

|---|---|

| 2023 | 688 |

| 2030 | 1,179.4 |

Why It’s Growing

The whole silicon carbide market is booming too. It was worth $4.2 billion in 2024 and could grow 34.5% every year until 2034. Why? Because things like electric cars and 5G networks need strong parts. Silicon carbide tubes are a big part of this. At Eshino Precision, we’re ready to meet this demand with top-quality tubes!

Comparison with Other Materials

Silicon Carbide vs. Others

Silicon carbide tubes are awesome, but how do they stack up against other materials? Let’s compare them to alumina and stainless steel. This will show why silicon carbide tubes are often the best pick for tough jobs. Check out our zirconia vs. alumina guide for more comparisons!

Comparison Table

| Feature | Silicon Carbide | Alumina | Stainless Steel |

|---|---|---|---|

| Heat Conductivity (W/mK) | 120 | 30 | 16 |

| Max Temp (°C) | 1650 | 1700 | 800 |

| Corrosion Resistance | Excellent | Good | Fair |

| Cost | High | Moderate | Low |

Why Silicon Carbide Wins

Silicon carbide tubes move heat better and fight corrosion like champs. They’re perfect for harsh places like chemical plants. Alumina is okay but not as good with heat. Stainless steel is cheaper but can’t handle high heat or acids. That’s why silicon carbide tubes are the go-to for energy and aerospace jobs.

Common Questions About Silicon Carbide Tubes

Your Questions Answered

People have lots of questions about silicon carbide tubes. Here are some common ones with simple answers to help you understand!

FAQs

- What’s so great about silicon carbide tubes? They’re super tough, handle heat up to 1650°C, and don’t get hurt by acids. This makes them last longer than metal. See our high-temperature guide.

- How are they made? We shape silicon carbide powder and bake it at super high temperatures, like 2000°C. This makes them strong and smooth. Check out our CNC machining guide.

- Who uses them? Industries like chemicals, power, and aerospace love them for their strength.

- How’s silicon carbide different from tungsten carbide? Silicon carbide tubes are ceramics for hot, corrosive jobs. Tungsten carbide is denser and used for cutting tools, not high heat.

- Do they need a lot of care? Nope! They’re super tough, but you should check for cracks now and then. See our wear resistance guide.

- Are they expensive? They cost more than metal but save money over time because they last longer.

Conclusion

Why Silicon Carbide Tubes Rock

Silicon carbide tubes are like the superheroes of ceramics. They’re super strong, handle crazy heat, and laugh at harsh chemicals. Whether it’s chemical plants, spaceships, or electric cars, these tubes make things work better and last longer. Plus, the market for them is growing fast, so they’re a smart choice for the future.

Eshino Precision Has You Covered

At Eshino Precision, we’re experts at making top-quality silicon carbide tubes. Our tubes are super precise, thanks to our fancy machines. We can make exactly what you need for your project. Want to learn more? Check out our blog for tons of ceramic tips!

External Resources

Ready to Transform Your Engineering Solutions?

No industrial challenge is too complex for Eshino. From precision ceramic rods and advanced bushings to customized nozzles and other high-performance components, we engineer solutions that combine exceptional durability, thermal resistance, and precision to meet your specific needs. Whatever your industry demands, Eshino delivers tailored expertise you can trust.