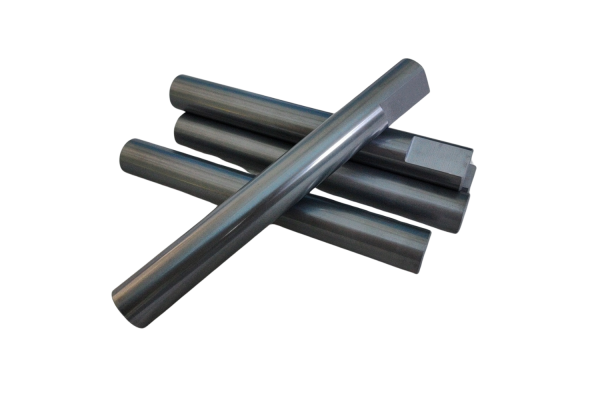

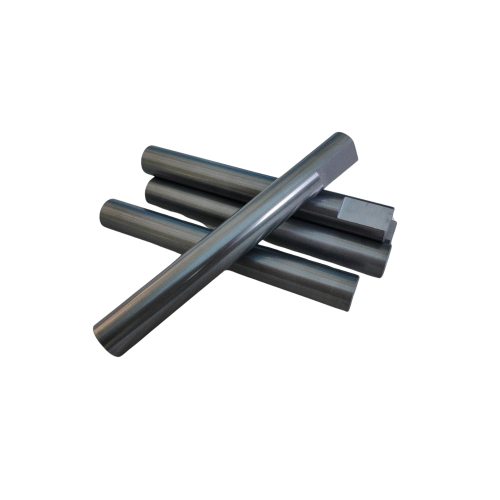

Engineered for extreme thermal cycling, dynamic loads, and demanding industrial applications.

Silicon nitride (Si3N4) is a high-performance advanced ceramic known for its unique balance of strength, toughness, and thermal shock resistance. Unlike many ceramics, Si₃N₄ rods can survive fast heating/cooling cycles, high mechanical stress, and wear conditions.

They are widely used in aerospace, automotive engines, precision bearings, and semiconductor tools.

| Parameter | Typical Value | Notes |

|---|---|---|

| Material | Silicon Nitride (Si₃N₄) | Available in hot-pressed, sintered grades |

| Color | Gray / Black | Sleek appearance |

| Density | ~3.2 g/cm³ | Lighter than alumina & zirconia |

| Flexural Strength | 800–1000 MPa | Very strong for a ceramic |

| Fracture Toughness | 6–7 MPa·m½ | Higher than alumina, lower than zirconia |

| Hardness | ~15 GPa | Good wear resistance |

| Max Temperature | ~1100 °C | Stable under heat |

| Thermal Shock Resistance | Excellent | Key advantage |

| Electrical Insulation | Good | Non-conductive |

| Diameter Range | 1–80 mm | Customizable |

| Length Range | Up to 800 mm | Longer on request |

| Surface Finish | Polished / Ground | Precision finish |

| Tolerances | ±0.01–0.05 mm | High precision achievable |

| MOQ | 1 piece | Prototype friendly |

Alumina Rods – high-temperature & insulating

Zirconia Rods – high toughness & impact resistance

Silicon Carbide Rods – extreme wear & chemical resistance

Silicon Nitride Rods – featured here: thermal shock + lightweight strength

| Property | Advantage for You |

|---|---|

| High Strength at Low Weight | Si₃N₄ is lighter than alumina/zirconia but with exceptional flexural strength, ideal for dynamic parts. |

| Outstanding Thermal Shock Resistance | Can handle rapid heating/cooling without cracking, perfect for engines or furnaces. |

| Wear & Fatigue Resistance | Long life in bearings, shafts, and moving components. |

| Corrosion Resistance | Stable in many acids, alkalis, and combustion gases. |

| Moderate Electrical Insulation | Good non-conductivity in many grades. |

| Dimensional Stability | Low thermal expansion ensures rods stay precise. |

| Reliable in Dynamic Loads | Handles vibration, impact, and rotational stress better than most ceramics. |

Automotive engines – glow plugs, turbocharger components, wear rods

Aerospace – turbine engine parts, lightweight load rods

Bearings & spindles – rolling elements and shafts in high-speed machinery

Semiconductors – rods for wafer handling in thermal cycling environments

Industrial furnaces – support rods that survive repeated heating/cooling

Pumps & compressors – lightweight, durable rods in corrosive or hot fluids

| Property / Problem | Metal Rods | Plastic/Resin Rods | Glass Rods | Si₃N₄ Rods |

|---|---|---|---|---|

| Wear Resistance | ⚠ Wears, fatigue | ❌ Soft, scratches | ⚠ Fragile | ✅ High |

| Corrosion Resistance | ❌ Rusts/oxidizes | ⚠ Limited | ⚠ Poor | ✅ Excellent |

| High Temp Resistance | ⚠ ~600 °C | ❌ ~250 °C | ⚠ Cracks | ✅ ~1100 °C |

| Thermal Shock Resistance | ⚠ Poor | ❌ Fails quickly | ❌ Shatters | ✅ Outstanding |

| Toughness | ✅ Good but corrodes | ⚠ Weak | ❌ Very brittle | ✅ High for a ceramic |

| Electrical Insulation | ❌ Conductive | ⚠ Limited | ⚠ Partial | ✅ Good |

| Cost vs Lifetime | ⚠ High maintenance | ⚠ Short life | ⚠ Fragile | ✅ Longer service life, less downtime |

Metal rods fatigue and corrode in hot, high-load environments.

Plastic/resin rods melt, deform, or fail under even moderate heat and load.

Glass rods shatter easily and cannot survive thermal cycling.

👉 If your application faces thermal shock, high loads, or dynamic movement, Silicon Nitride (Si₃N₄) Ceramic Rods are the solution: lightweight, strong, and resistant to sudden temperature changes.

| Feature / Property | Alumina (Al₂O₃) | Zirconia (ZrO₂) | Silicon Nitride (Si₃N₄) | Silicon Carbide (SiC) |

|---|---|---|---|---|

| Max Operating Temperature | ✅ ~1550 °C | ⚠ ~1000 °C | ✅ ~1100 °C | ✅ ~1400–1600 °C |

| Toughness | ⚠ Moderate | ✅ Very High | ✅ Good | ⚠ Moderate |

| Wear Resistance | ✅ Good | ✅ Excellent | ✅ High | ✅ Extreme |

| Density | Medium (~3.9 g/cm³) | Heavy (~6.0 g/cm³) | Light (~3.2 g/cm³) | Medium (~3.1 g/cm³) |

| Thermal Shock Resistance | ⚠ Moderate | ✅ Good | ✅ Excellent | ⚠ Moderate |

| Electrical Insulation | ✅ Excellent | ✅ Excellent | ✅ Good | ⚠ Semi-conductive |

| Best Fit Use | High heat, insulation | Impact/vibration | Dynamic loads, thermal cycles | Abrasive, corrosive, high wear |

Background:

A German automotive supplier used metal rods in turbochargers that failed due to fatigue and thermal cycling.

Solution:

They switched to Si₃N₄ rods with high thermal shock resistance.

Results:

Survived >100,000 cycles without cracks

Reduced failures by 80%

Improved engine reliability

Background:

A Japanese semiconductor company needed rods for wafer handling under fast heat/cool cycles. Glass and alumina rods cracked.

Solution:

Si₃N₄ rods were chosen for their low thermal expansion and shock resistance.

Results:

Withstood rapid thermal cycles with zero breakage

Improved wafer handling yield by 15%

Lower maintenance downtime

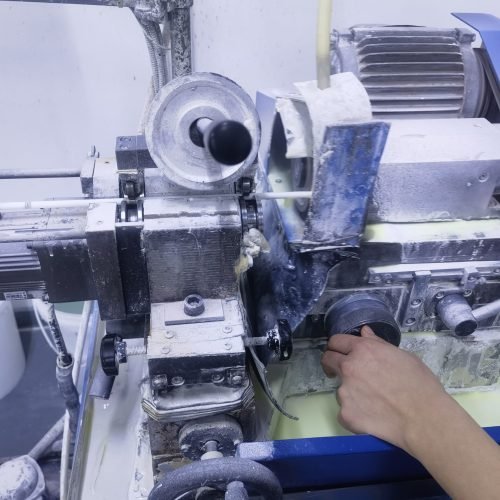

Powder → Forming → Sintering → CNC/Grinding → Inspection → Packaging → Delivery

It is lighter, more resistant to thermal shock, and stronger under dynamic loads.

Typically up to ~1100 °C.

Yes, silicon nitride is the best ceramic for thermal shock resistance.

Less brittle than alumina, but not as tough as zirconia.

1–80 mm diameter, up to 800 mm length, customizable.

20+ Years Ceramic Expertise – trusted by Apple, BYD, Huawei, and global leaders

Advanced Production – ISO9001 certified, SOP-controlled, and Apple-audited factory

Fast Lead Time – over 95% on-time delivery, higher than industry average

Custom Solutions – small MOQ (from 1 piece) to mass production, tailored to your design

Full Technical Support – our ceramic engineers help you choose the right grade and design

We will get back to you within 12 hours.