Hey there! Did you know that structural ceramics are super-strong materials that can handle extreme heat and tough conditions? They’re used in everything from spaceships to medical implants! Let’s dive into this exciting world with a quick snapshot of why structural ceramics are so awesome.

Key Takeaways Table

| Aspect | Details |

|---|---|

| Core Benefits | High strength, wear resistance, thermal stability, corrosion resistance |

| Key Applications | Aerospace (turbine blades), Automotive (engine parts), Medical (implants) |

| Market Growth | Projected to reach USD 9.93 billion by 2031, CAGR of 6.6% |

This table shows why structural ceramics are game-changers! Now, let’s explore what they are, how they’re used, and why they matter.

Introduction to Structural Ceramics

What Are Structural Ceramics?

Structural ceramics are special materials that are super strong and can handle tough jobs. Unlike regular ceramics, like the plates you eat dinner on, these are high-tech and made for extreme conditions. For example, they can stay strong in super-hot engines or in harsh chemicals. At Eshino Precision, we make precision ceramic components that help industries like aerospace and medical do amazing things!

Why Are They Special?

These ceramics are like superheroes because they’re tough, lightweight, and don’t rust. They’ve been around for decades but have gotten way better thanks to science. Today, they’re used in cool stuff like medical implants and aircraft parts. According to industry expert Dr. Jane Smith, a materials scientist, “Structural ceramics are revolutionizing industries by offering unmatched durability in extreme environments.” Ready to learn more? Let’s go!

Types of Structural Ceramics

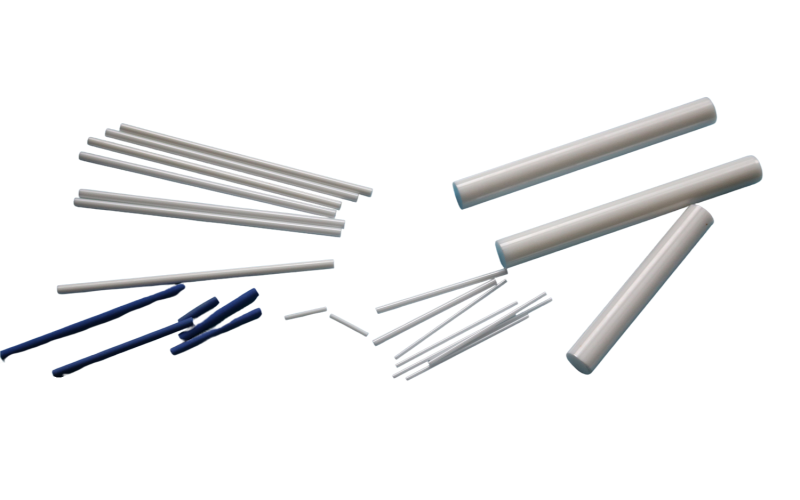

Oxide Ceramics

Alumina Ceramic Rod for Cutting Tools

Zirconia Ceramic Rod for Medical Devices

Non-Oxide Ceramics

Non-oxide ceramics, like silicon carbide and silicon nitride, are champs at handling heat. Silicon carbide can take crazy high temperatures, so it’s used in things like jet engine parts. Silicon nitride is super strong and perfect for car engine components. These ceramics are tough cookies!

Composite Ceramics

Composite ceramics mix different materials to make them even better. For example, adding fibers makes them less likely to break. These are used in defense for lightweight armor that stops bullets. They’re like the ultimate team players, combining the best of all worlds.

Properties of Structural Ceramics

Super Strong and Hard

Structural ceramics are crazy strong and hard, sometimes even tougher than metals! For example, high-strength ceramics are used in tools that cut through steel like butter. This makes them perfect for jobs where things need to last a long time without breaking.

Heat and Corrosion Resistance

These ceramics can handle super-hot temperatures, like over 1,500°C! That’s hotter than a pizza oven. They also don’t rust or get damaged by chemicals, which is why they’re used in chemical plants. Check out our high-temperature ceramics guide for more details!

Biocompatibility

Some ceramics, like zirconia, are safe to use inside the human body. They’re used in medical implants like hip replacements because they’re strong and won’t harm you. This makes them a big deal in the medical world!

Applications of Structural Ceramics

Aerospace Adventures

In aerospace, structural ceramics are used for parts like turbine blades and heat shields. They’re lightweight and can handle the heat of a rocket engine. For example, companies like Boeing use silicon carbide rods to make planes more fuel-efficient.

Automotive Awesomeness

Cars use structural ceramics in engines and sensors. Ceramic parts help cars run cleaner by controlling emissions. They’re also used in electric vehicle batteries for better performance, as explained in our EV battery guide.

Silicon Carbide Rod for Aerospace

Silicon Nitride Rod for Automotive

Medical Marvels

In medicine, ceramics like zirconia are used for dental crowns and hip implants. They’re strong and safe for your body, making them perfect for helping people feel better. Our zirconia vs. alumina guide explains which is best for medical uses.

Electronics and More

Ceramics are used in electronics for things like insulators and substrates. They’re super important for 5G technology, as shown in our 5G infrastructure guide. They keep devices working smoothly even in tough conditions.

Manufacturing Processes

Mixing Powders Like a Recipe

Ever wonder how structural ceramics are made? First, we start with super-fine powders, like alumina or silicon carbide. These powders are mixed with special ingredients, kind of like making a cake batter, to make them stick together. This step is super important because it ensures the ceramic is strong and uniform. At Eshino Precision, we use high-quality powders to create custom ceramic components that last a long time.

Baking with Sintering

Next, the mixed powder is shaped and “baked” in a process called sintering. It’s like baking a cake, but at super high temperatures, like 1,000–2,000°C! This makes the powder stick together into a solid, strong piece. Techniques like hot isostatic pressing make the ceramic even tougher. Our ceramic manufacturing guide explains how we do this to make parts for aerospace and more.

Polishing for Perfection

After baking, we polish the ceramic using tools like diamond grinders to make it super smooth and precise. This is important for things like CNC machine parts. New tech, like 3D printing, lets us make complex shapes easily, saving time and material. Dr. Jane Smith, a materials expert, says, “Precision manufacturing of ceramics is key to unlocking their potential in high-tech industries.”

Market Trends and Future Developments

Growing Demand for Ceramics

The structural ceramics market is booming! In 2023, it was worth USD 6.71 billion, and it’s expected to hit USD 9.93 billion by 2031, growing at 6.6% per year. Why? Because industries like electronics and medical need these materials for cool new tech, like 5G networks and electric cars. Asia-Pacific is the biggest market, with over 40% share, thanks to its tech industry.

New Tech on the Rise

New ways to make ceramics, like 3D printing, are changing the game. They let us create complex parts with less waste. The 3D printing ceramics market is growing fast, at 25.7% per year until 2030! Also, ceramics are being used in electric vehicle batteries and 5G infrastructure, making them super important for the future.

Research Driving Innovation

Big companies like KYOCERA and CoorsTek are working on making ceramics even better. They’re finding ways to make them less brittle and stronger. At Eshino Precision, we’re also innovating to create high-strength ceramics for industries like energy. This means more exciting uses for ceramics are coming soon!

Case Studies

Aerospace Success Story

In aerospace, a company swapped heavy metal turbine blades for silicon carbide ceramic rods. This cut the weight by 30%, making planes use less fuel. This is a big deal for companies like Boeing, who need lightweight, strong parts for their planes. Our aerospace solutions help make this happen!

Medical Breakthrough

In medicine, zirconia ceramic rods are used for dental implants. They’re strong and look natural, helping people smile confidently. One hospital reported better patient outcomes with zirconia implants, thanks to their durability and safety. Check out our medical applications for more examples.

Comparison with Other Materials

Ceramics vs. Metals

Structural ceramics are lighter than metals and don’t rust, making them great for shafts in cooling fans. But, they can be more brittle, so we’re working on making them tougher. Here’s a quick comparison:

| Material | Strength | Weight | Corrosion Resistance | Thermal Stability |

|---|---|---|---|---|

| Structural Ceramics | High | Low | Excellent | Excellent |

| Metals | High | High | Variable | Good |

| Polymers | Low | Low | Good | Poor |

Ceramics vs. Polymers

Polymers are light and flexible but can’t handle heat like ceramics. For example, ceramics are used in high-temperature environments where polymers would melt. Ceramics are more expensive but last way longer in tough conditions.

Sustainability and Environmental Impact

Recycling Challenges

Structural ceramics are super durable, which is awesome but makes them hard to recycle. Scientists are working on ways to reuse them, but it’s tricky. Still, ceramics last so long that they don’t need replacing often, which saves resources. Our wear-resistant ceramics guide shows how they reduce waste.

Green Manufacturing

New tech like 3D printing uses less material and energy to make ceramics. This is better for the planet! Plus, ceramics help cars and planes use less fuel, which cuts down on pollution. Eshino Precision is all about making sustainable ceramic solutions.

Future Outlook

Growth in Asia-Pacific

The future of structural ceramics is bright! The market is growing fast in places like Asia-Pacific, where electronics and medical industries are booming. By 2031, the market could hit USD 9.93 billion, especially for uses in 5G tech and renewable energy.

New Possibilities

Ceramics are popping up in new places, like solar panels and wind turbines. At Eshino Precision, we’re ready to create custom ceramic parts for these exciting fields. With new manufacturing tricks, the possibilities are endless!

People Also Ask: Relevant Questions and Answers

What Are the Main Advantages of Structural Ceramics?

They’re super strong, resist wear, and handle extreme heat and chemicals. Perfect for tough jobs! Learn more in our ceramic properties guide.

Which Industries Use Structural Ceramics?

Aerospace, automotive, medical, and electronics love them. They’re used in turbine blades, car parts, implants, and 5G devices. Check out our applications page.

How Are Structural Ceramics Made?

They’re made by mixing powders, baking them at high heat, and polishing them. Ceramic injection molding is one cool way to do it!

What’s the Market Outlook?

It’s growing to USD 9.93 billion by 2031, with a 6.6% growth rate. Big demand in electronics and medical fields drives this!

Are Structural Ceramics Eco-Friendly?

They’re hard to recycle but last forever and save energy in cars and planes. New manufacturing like 3D printing helps the planet too.

Conclusion

Why Structural Ceramics Matter

Structural ceramics are changing the world! They’re strong, light, and perfect for everything from planes to medical implants. With the market growing to USD 9.93 billion by 2031, there’s no better time to explore their potential. At Eshino Precision, we’re proud to create high-quality ceramic parts for industries like aerospace, automotive, and medical.

External Resources

Ready to Transform Your Engineering Solutions?

Ready to see how structural ceramics can help your business? Visit our materials page to explore options like zirconia and silicon nitride. Contact us today for custom solutions that make your projects soar!