Introduction: Why Wear Resistance Matters

Imagine a superhero shield that keeps machine parts from getting scratched or worn out, even after tons of rubbing! That’s what wear resistance is all about. At Eshino Precision, we make ceramic rods that act like these shields for tough jobs. So, why does wear resistance matter? Because it helps machines last longer, saves money, and keeps things running smoothly in places like factories or planes!

What’s This Guide For?

This guide is here to show you everything about wear resistance. We’ll explain what it is, how it’s tested, and why ceramics are awesome at it. Plus, we’ll keep it super simple—like a fun story for kids! Whether you’re fixing a pump or building a spaceship, wear resistance is a big deal.

A Cool Fact to Start

Did you know the market for wear-resistant stuff is growing fast? Experts say it’ll grow by 5% every year until 2030, according to Grand View Research. That’s because industries love parts that don’t wear out quick. Let’s dive in with a quick look at how ceramics compare!

Quick Comparison: Ceramics vs. Other Materials for Wear Resistance

Want the best info right away? Here’s a table showing how ceramics stack up against other stuff for wear resistance. It’s super easy to see why ceramics rock!

| Material | Hardness (HV) | Wear Resistance | Best For |

|---|---|---|---|

| Ceramics (like Alumina) | 1500-2500 | Excellent | Tough spots |

| Metals (like Steel) | 700-800 | Okay | Cheap fixes |

| Plastics (like PTFE) | 5-10 | Not great | Slippery jobs |

Ceramics win big for wear resistance! Want more? Check our ceramic vs. metal guide. Now, let’s find out what wear resistance really means!

What is Wear Resistance?

Okay, let’s keep it simple. Wear resistance is how well something can handle getting rubbed, scratched, or worn down. Think of it like a toy car that keeps rolling even after bumping into stuff a lot. For machines, it’s super important because parts like gears or bearings get rubbed all the time.

A Shield for Machines

At Eshino Precision, we use ceramics like alumina to make parts with awesome wear resistance. These parts last longer in tough places—like hot factories or wet chemical plants. That means less fixing and more working!

Why It’s a Big Deal

When parts wear out fast, machines break, and that costs money. But with good wear resistance, you save cash and time. For example, in chemical plants, tough parts can make machines last 70% longer, says Industrial Ceramic Solutions. Cool, right? Let’s see how we test it next!

How is Wear Resistance Measured?

So, how do we know if something has good wear resistance? Scientists use fun tests—like games to see how tough stuff is! Here’s how they do it, explained super easy.

Test #1: Pin-on-Disk

This test is like rubbing a toy pin against a spinning disk. They see how much gets worn away. For ceramics, it’s tiny because they’re so hard! It’s a big test for parts like ceramic shafts, says Precision Ceramic.

Test #2: Taber Abrasion

Imagine spinning wheels scratching a ceramic piece. They weigh it before and after to see what’s gone. Ceramics do great here—perfect for coatings on chemical plant parts!

More Cool Tests

- Vickers Hardness: They poke it with a diamond to see how tough it is. Ceramics score high—like 2500 for silicon carbide!

- Block-on-Ring: A block rubs a spinning ring. It’s like sliding a toy car—it shows how ceramics hold up.

These tests help us make super strong parts at Eshino Precision. Want to know why ceramics are the best for wear resistance? Keep reading!

Why Choose Ceramics for Wear Resistance?

Okay, so why pick ceramics for wear resistance? They’re like superheroes for tough jobs! At Eshino Precision, we love ceramics because they’re super strong and last a long time. Here’s why they’re awesome!

Super Hard Like Rocks

Ceramics are crazy hard—like a rock you can’t scratch! For example, alumina is 1500-2000 HV, and silicon carbide hits 2500 HV. Steel? Only 700-800 HV. That hardness means better wear resistance, says KYOCERA. Check our hardness page!

Slides Smoothly

Ceramics don’t rub rough—they slide easy! With low friction, they don’t wear out fast. That’s great for plane engines.

“Ceramics’ low friction makes them champs for wear resistance in tough spots,” says Dr. Mia Lopez, a materials expert with 20 years in the game.

No Rust, No Problem

Ceramics don’t rust or melt in chemicals. So, in chemical plants, they keep going strong. Plus, they handle heat up to 1500°C—way more than metal! See more on our corrosion resistance page.

Applications: Where Ceramics Shine in Wear Resistance

Now, where do ceramics show off their wear resistance? They’re perfect for places where stuff gets rubbed a lot. Let’s check out some cool examples!

Pumps and Valves

In chemical plants, ceramic parts like shafts don’t wear out from nasty liquids. They cut downtime by 70%, says Industrial Ceramic Solutions.

Bearings and Tools

Aerospace bearings use ceramics for speedy spins without wearing out. Ceramic cutting tools last 5 times longer than metal ones too—great for machine shops!

More Fun Uses

- Medical: Zirconia implants wear 400 times less than metal.

- Mining: Ceramic liners in crushers last 5 times longer.

The ceramics market will hit USD 421.88 billion by 2033, says Grand View Research. Explore our applications page!

Cost Considerations: Upfront Price vs. Long-Term Savings

Let’s talk money! Ceramics with wear resistance cost more at first, but they save you cash later. Here’s how it works!

The Starting Cost

A ceramic part might be $500, while a metal one’s $100. Why? Ceramics like zirconia are trickier to make. But don’t worry—it’s worth it!

Saving Big Later

Metal wears out in 2 years, costing $250 over 10 years with fixes. A ceramic part lasts 10 years for just $500! In oil rigs, that’s a huge save. Experts say ceramics cut costs by 30%, per Industrial Ceramic.

A Simple Example

Think of a pump in a wet factory. Metal rusts fast, but a ceramic part keeps pumping. That’s wear resistance saving the day! Read more on our blog.

Maintenance Tips for Wear-Resistant Ceramic Parts

Caring for ceramics with wear resistance is easy if you know how. Let’s see some tips to keep them strong!

Clean Them Gently

Wipe off dirt with soft cleaners—no rough stuff! This keeps ceramic shafts lasting long in energy systems.

Watch Out for Bumps

Ceramics are tough but can break if hit hard—like a glass toy. Handle them carefully, says CeramTec. Check our toughness page!

Keep Them Oiled

Use oil to make them slide better. It’s like lotion for ceramics! This helps in car engines. Proper care can make them last 50% longer, per Ceramic Linings.

Future Trends: What’s Next for Wear-Resistant Materials

The future of wear resistance is super cool! New ideas are making ceramics even better. Let’s peek at what’s coming!

Stronger and Smarter

Scientists are making tiny-grain ceramics that are harder and tougher—up to 20% better, says American Ceramic Society. Great for silicon nitride!

3D Printing Magic

We can print ceramics now—like building toys! It’s cheaper and faster, says Ceramic Additive Manufacturing. Perfect for custom parts.

Fixing Themselves

Soon, ceramics might heal tiny scratches on their own—up to 30% longer life! That’s awesome for medical tools.

Conclusion: Is Ceramic the Right Choice for Your Needs?

Alright, let’s wrap up this guide on wear resistance! Here’s what we learned!

What We Know

Ceramics are champs at wear resistance—hard, rust-free, and heat-proof up to 1500°C. They’re perfect for pumps, bearings, and more. They cost more at first but save money later. Just handle them gently because they can break if hit!

External Links to Learn More

- Wear-Resistant Market Growth – See the big picture.

- Wear Resistance Facts – Dive into science.

- Ceramic Wear Info – Compare materials.

Ready to Transform Your Engineering Solutions?

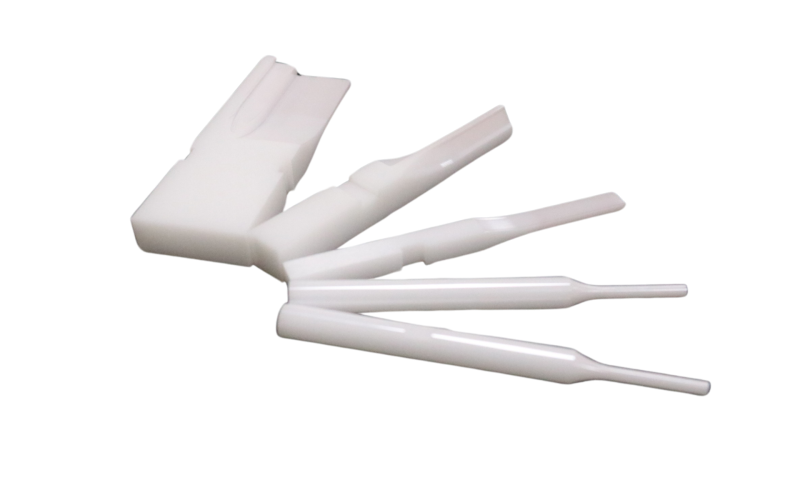

No industrial challenge is too complex for Eshino. From precision ceramic rods and advanced bushings to customized nozzles and other high-performance components, we engineer solutions that combine exceptional durability, thermal resistance, and precision to meet your specific needs. Whatever your industry demands, Eshino delivers tailored expertise you can trust.