Key Takeaways: Why Wear-Resistant Ceramics Matter

Imagine materials so strong they can protect machines from wearing out, even in the toughest jobs! Wear-resistant ceramics are super tough and help equipment last longer. Here’s a quick table to show why they’re awesome:

| Aspect | Details |

|---|---|

| Definition | Advanced materials that fight wear and tear |

| Types | Alumina, Silicon Carbide, Zirconia, Silicon Nitride |

| Key Benefits | Longer equipment life, lower repair costs |

| Industries | Mining, manufacturing, medical, chemical |

| Market Size | USD 107 billion in 2023, growing 4.2% yearly |

This table gives you the big picture fast. Next, let’s dive into what makes wear-resistant ceramics so special at Eshino Precision.

Introduction

What’s This All About?

Have you ever wondered how machines keep working in super tough places, like mines or factories? The answer is wear-resistant ceramics. These are like superheroes for machines, protecting them from damage caused by rubbing, scraping, or harsh chemicals. At Eshino Precision, we make these tough materials to help businesses save money and keep their equipment running smoothly.

Why Should You Care?

Wear-resistant ceramics are important because they make machines last longer. For example, in a mine, equipment gets worn out fast by rocks and dirt. But with ceramics, those machines stay strong for years! Plus, they help the environment by reducing waste. In this guide, we’ll explain everything in a simple way, so you can understand how these ceramics work and why they’re a big deal.

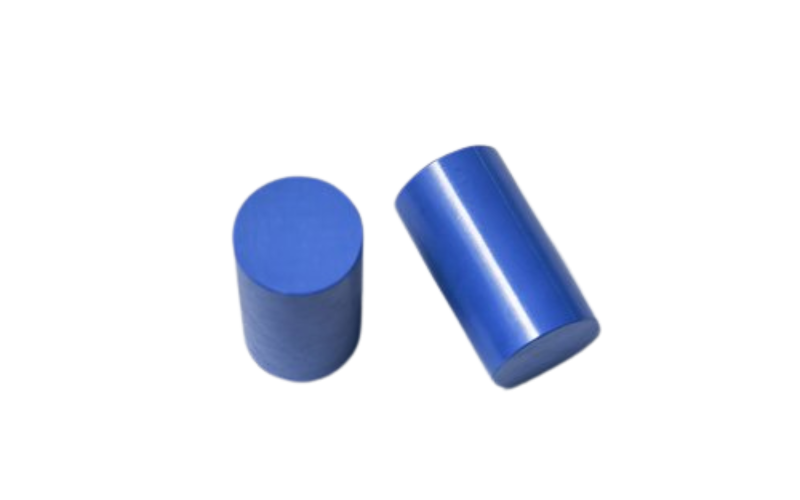

Eshino Precision’s Role

At Eshino Precision, we’re experts in making ceramic materials like rods and components for all kinds of industries. Whether it’s for a factory or a hospital, we’ve got the right ceramic to handle tough jobs. Let’s explore what wear-resistant ceramics are and how they can help you!

“Wear-resistant ceramics are game-changers for industries. They cut downtime and boost efficiency, making equipment last longer than ever,” says Dr. Jane Lin, a materials scientist with 20 years in ceramic engineering.

What Are Wear-Resistant Ceramics?

The Basics

Wear-resistant ceramics are special materials designed to stop machines from getting damaged. Think of them as super-strong shields. They’re made from stuff like alumina, silicon carbide, zirconia, and silicon nitride. These ceramics are way harder than metal, so they don’t wear out easily.

Why Are They So Tough?

These ceramics can handle crazy conditions, like super high heat or strong chemicals. For instance, in a chemical plant, machines deal with acids that could destroy metal parts. But ceramics stay strong! They’re also great for places where things rub together a lot, like in mining equipment. This toughness makes them perfect for many jobs.

Where Do They Fit In?

You’ll find wear-resistant ceramics in all sorts of industries. They’re used in mining, chemical plants, and even hospitals. At Eshino Precision, we make ceramic rods that use these materials to keep machines running longer. Curious about the different types? Let’s check them out next!

Silicon Carbide Rod: Super Tough for Heat

Zirconia Rod: Strong Against Impacts

Types of Wear-Resistant Ceramics

Alumina Ceramics

Silicon Carbide Ceramics

Next, we have silicon carbide. This one’s like the king of hardness! It’s almost as tough as a diamond and can work in really hot places, like aerospace equipment. It’s perfect for parts that need to last a long time under tough conditions.

Zirconia Ceramics

Zirconia is another awesome ceramic. It’s super strong against bumps and scratches, so it’s used in things like medical tools. If something needs to take a hit without breaking, zirconia’s your pick.

Silicon Nitride Ceramics

Lastly, there’s silicon nitride. This one’s tough and durable, great for heavy machines like CNC machines. It’s strong enough to handle rough jobs without wearing out. Want to compare these? Check out our guide on zirconia vs. alumina or silicon nitride vs. silicon carbide.

Properties That Make Ceramics Wear-Resistant

Why Are They So Strong?

Wear-resistant ceramics are like superheroes because they have special powers that make them tough. These powers, or properties, let them stand up to rough conditions. For example, they’re super hard, which means they don’t get scratched easily. At Eshino Precision, we use these properties to make ceramic components that last a long time.

Key Properties

Here’s what makes wear-resistant ceramics so awesome:

- Hardness: They’re harder than most metals. For example, silicon carbide has a hardness of 28-34 GPa, almost like a diamond!

- Corrosion Resistance: They don’t get damaged by chemicals. This is great for chemical plants.

- Thermal Stability: They can handle super hot temperatures, over 1000°C, without melting or breaking.

- Low Friction: Some ceramics, like silicon carbide, slide smoothly, which reduces wear in moving parts.

Hardness Table

Check out how hard these ceramics are compared to each other:

| Ceramic Type | Vickers Hardness (GPa) |

|---|---|

| Alumina | 15-20 |

| Silicon Carbide | 28-34 |

| Zirconia | 12-15 |

| Silicon Nitride | 14-18 |

These properties make ceramic rods perfect for tough jobs. Want to know where they’re used? Let’s find out!

Applications: Where Are They Used?

Industries That Love Ceramics

Wear-resistant ceramics are used in tons of places because they’re so tough. Imagine a mine where rocks are constantly rubbing against machines. Ceramics protect those machines! At Eshino Precision, we make ceramics for many industries. Here’s where you’ll find them:

Top Applications

- Mining: Mining equipment uses ceramic liners in chutes and pipes to handle rough materials like rocks and dirt.

- Manufacturing: Tools and molds in factories last longer with ceramics.

- Chemical Plants: Valves and pumps stay strong against harsh chemicals.

- Medical: Implants like hip joints use zirconia because it’s safe and durable.

- Energy: Power plants use ceramics in parts that face high heat and wear.

Real-Life Impact

For example, in aerospace, silicon carbide rods help equipment handle extreme conditions. This keeps planes and rockets running smoothly. Ceramics make a big difference by keeping machines working longer and better.

“In mining, wear-resistant ceramics can double the lifespan of equipment, saving companies millions in repairs,” says Mark Thompson, a mining industry consultant.

Benefits of Wear-Resistant Ceramics

Why Choose Ceramics?

Using wear-resistant ceramics is like giving your machines a superpower. They don’t just protect equipment; they save money and help the planet too. At Eshino Precision, we see how ceramics change the game for businesses. Let’s look at the top benefits.

Big Wins

- Longer Equipment Life: Ceramics last way longer than metal. For example, alumina liners in mining can last 50% longer than metal ones.

- Less Downtime: Machines break down less, so you don’t have to stop work to fix them. This can cut downtime by 30% in some cases!

- Cost Savings: Yes, ceramics cost more at first, but they save money over time by reducing repairs.

- Eco-Friendly: Longer-lasting parts mean less waste, which is great for the environment.

Why It Matters

Imagine a factory that stops working because a part wore out. That’s expensive! With wear-resistant ceramics, factories keep running smoothly. Plus, businesses like automotive companies use ceramics to make cars more efficient. Ready to pick the right ceramic? Let’s see how!

Silicon Carbide Rod: Super Tough for Heat

Ceramic Liner: Protects Mining Equipment

How to Pick the Right Ceramic

Steps to Choose Wisely

Choosing the right wear-resistant ceramic can feel tricky, but it’s easy if you follow these steps. At Eshino Precision, we help businesses find the perfect ceramic for their needs. Here’s how to do it:

- Check the Wear Type: Is the machine dealing with rubbing (abrasion) or hitting (impact)? Silicon carbide is great for abrasion, while zirconia handles impacts.

- Look at Conditions: Does it get super hot or deal with chemicals? High-temperature ceramics like silicon carbide work best for heat.

- Weigh Cost vs. Benefits: Alumina is cheaper, but silicon nitride might be worth it for tough jobs.

- Ask Experts: Talk to us at Eshino Precision to get advice tailored to your needs.

Why It’s Important

Picking the right ceramic means your machines will work better and last longer. For example, using the wrong ceramic in a chemical plant could lead to breakdowns. Our comparison guides can help you decide. Next, let’s see what’s new in ceramics!

Recent Advances in Ceramics

What’s New in Wear-Resistant Ceramics?

Wear-resistant ceramics are getting even better thanks to new technology! Scientists are finding ways to make them tougher and more useful. At Eshino Precision, we stay on top of these changes to bring you the best ceramic solutions. So, what’s new? Let’s check it out!

Cool New Ideas

First, there are composite ceramics. These mix two materials, like alumina and zirconia, to make them super strong. For example, zirconia-toughened alumina (ZTA) is hard and doesn’t break easily. Next, nano-ceramics use tiny particles to make ceramics even tougher. Also, 3D printing lets us create custom ceramic parts in cool shapes for specific jobs.

Why It Matters

These advances mean ceramics can do more than ever. For instance, new composites are perfect for aerospace parts that need to be light but strong. Plus, 3D printing makes it faster to get exactly what you need. As Dr. Sarah Kim, a ceramics researcher, says:

“New ceramic composites and 3D printing are revolutionizing industries by offering stronger, custom solutions for tough environments.”

These updates make ceramics the future of high-tech materials!

Real-World Examples: Case Studies

Seeing Ceramics in Action

Wear-resistant ceramics aren’t just ideas—they really work! Let’s look at some real stories from industries using ceramics from Eshino Precision. These examples show how ceramics save time and money.

Success Stories

- Mining: In a mine, alumina ceramic liners in slurry pumps lasted 50% longer than metal ones. This cut downtime by 30%, keeping the mine running smoothly.

- Automotive: Silicon nitride bearings in car engines reduced friction, making cars faster and more efficient. Check out our automotive solutions.

- Surface Processing: Blast nozzles made of silicon nitride lasted over 1000 hours in rough conditions, beating metal nozzles by a long shot.

Why It’s Awesome

These stories prove that wear-resistant ceramics make a big difference. They help businesses save money and keep machines running. Want to see how ceramics can help your industry? Let’s talk about the market next!

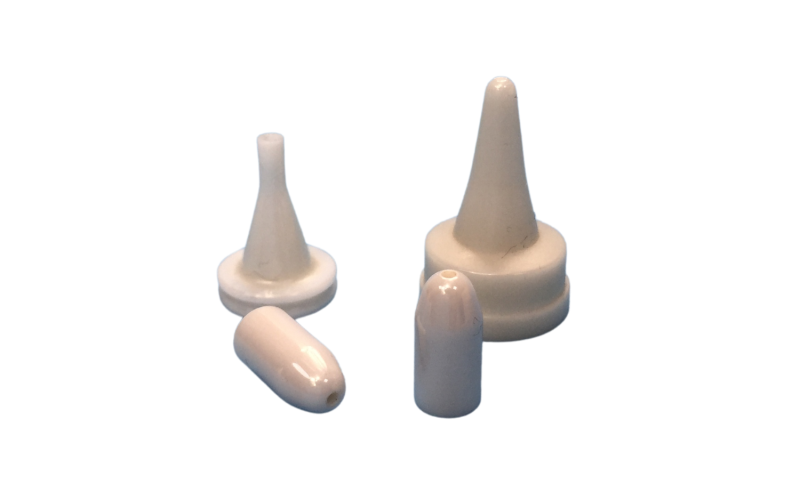

Alumina Liner: Tough for Mining Pumps

Ceramic Nozzle: Long-Lasting for Blasting

Market Trends and Future Outlook

How Big Is the Ceramic Market?

The world loves wear-resistant ceramics, and the market is growing fast! In 2023, the advanced ceramics market, which includes wear-resistant ones, was worth USD 107 billion. Experts say it’ll grow by 4.2% every year until 2030. At Eshino Precision, we’re excited to be part of this growth.

Key Trends

- Alumina Ceramics: Worth USD 2.6 billion in 2023, expected to hit USD 4.2 billion by 2032.

- Ceramic Tubes: Growing from USD 1.5 billion in 2023 to USD 2.9 billion by 2032.

- Smart Tech: New ceramics might have sensors to check wear in real-time.

- Green Manufacturing: Making ceramics with less energy to help the planet.

What’s Next?

The future looks bright! Industries like medical and electronics are using more ceramics. Plus, places like China and India are buying tons of them. This means more jobs for ceramics in semiconductors and energy. Let’s answer some common questions next!

Common Questions Answered

What People Want to Know

People often ask about wear-resistant ceramics. Here are simple answers to help you understand them better, straight from Eshino Precision.

Top Questions

- What’s the hardest ceramic? Silicon carbide is the toughest, with a hardness of up to 34 GPa, almost like a diamond!

- How are they tested? We use tests like the ASTM G65 abrasion test to see how tough they are against rubbing.

- Are they expensive? They cost more upfront but save money over time because they last longer. Learn more about ceramic hardness.

- Can they handle heat? Yes! Ceramics like alumina work at over 1000°C, perfect for hot environments.

- What industries use them? Mining, automotive, chemical, and medical industries love ceramics.

Why It Helps

These answers show why wear-resistant ceramics are so popular. They’re tough, save money, and work in crazy conditions. Check out our blog for more tips!

Conclusion

Why Ceramics Are a Big Deal

Wear-resistant ceramics are like magic for machines. They make equipment last longer, save money, and even help the environment. Whether it’s alumina in a mine or zirconia in a hospital, these materials are superstars. At Eshino Precision, we’re proud to make ceramic rods and parts that help businesses succeed.

External Resources

Want to learn more? Here are some great sources:

- Grand View Research: Advanced Ceramics Market – Market size and growth trends.

- Precision Ceramics: Wear-Resistant Ceramics – Details on ceramic types and uses.

- Kyocera: Ceramic Hardness – Info on ceramic properties.

- Syalons: Ceramics in Equipment Life – Case studies and benefits.

Ready to Transform Your Engineering Solutions?

Ready to make your machines tougher? Contact Eshino Precision today! We’ll help you find the perfect wear-resistant ceramic for your needs, whether it’s for mining, cars, or medical tools. Visit our contact page or check out our blog for more ideas. Let’s make your equipment unstoppable!