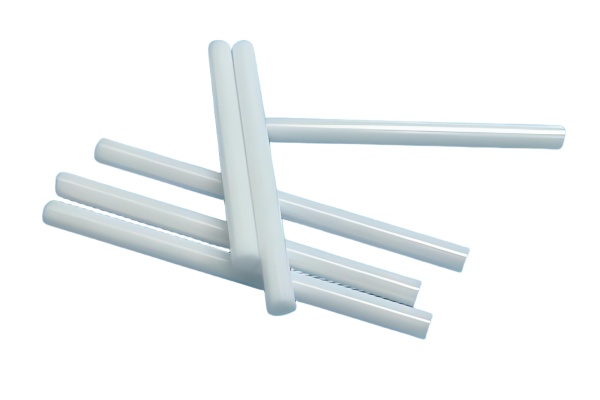

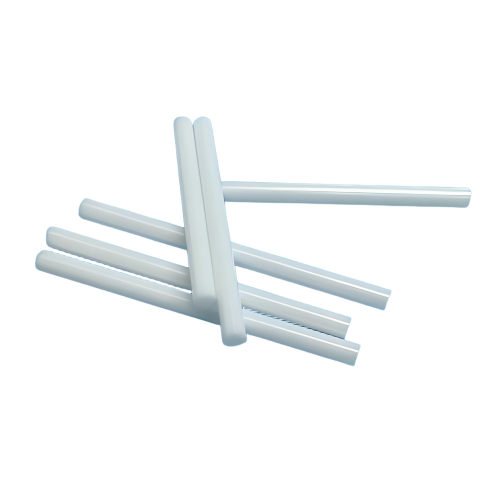

The toughest advanced ceramic rods for demanding applications in pumps, medical devices, aerospace, and more.

Zirconia (ZrO₂) is a high-performance advanced ceramic known for its exceptional toughness, smooth surface finish, and wear resistance. Zirconia rods are widely used in precision machinery, pumps, medical devices, and aerospace applications.

Unlike most ceramics, zirconia offers a rare balance: strength + toughness, making it less brittle and more reliable under impact, vibration, or misalignment.

| Parameter | Typical Value | Notes |

|---|---|---|

| Material | Zirconia (ZrO₂, Y-TZP or Mg-PSZ) | Different grades available |

| Color | White / Ivory | Smooth, aesthetic |

| Density | ~6.0 g/cm³ | Heavier than alumina or Si₃N₄ |

| Flexural Strength | 900–1200 MPa | Very high |

| Fracture Toughness | 8–10 MPa·m½ | Highest among ceramics |

| Hardness | 1200 HV | Excellent wear resistance |

| Max Temperature | ~1000 °C | Depends on grade |

| Electrical Insulation | Excellent | Dielectric strength >10 kV/mm |

| Diameter Range | 1–100 mm | Customizable |

| Length Range | Up to 1000 mm | Long rods available |

| Surface Finish | Polished / Ground | Smooth, low friction |

| Tolerances | ±0.01–0.05 mm | Precision achievable |

| MOQ | 1 piece | Prototype friendly |

Alumina Rods – best for high temperatures and electrical insulation

Silicon Nitride Rods – excellent thermal shock resistance and lighter weight

Silicon Carbide Rods – extreme wear and chemical resistance

Zirconia Rods – featured here: best toughness + smooth finish

| Property | Advantage for You |

|---|---|

| High Fracture Toughness | Zirconia is up to 10× tougher than alumina, making it less likely to crack under impact or stress. |

| Excellent Wear Resistance | Smooth surface and high hardness reduce friction, extending part life in sliding or rotating contact. |

| Corrosion & Chemical Resistance | Inert against most acids, alkalis, and fluids—where metals would rust. |

| Thermal Stability | Operates reliably up to ~1000 °C depending on grade. |

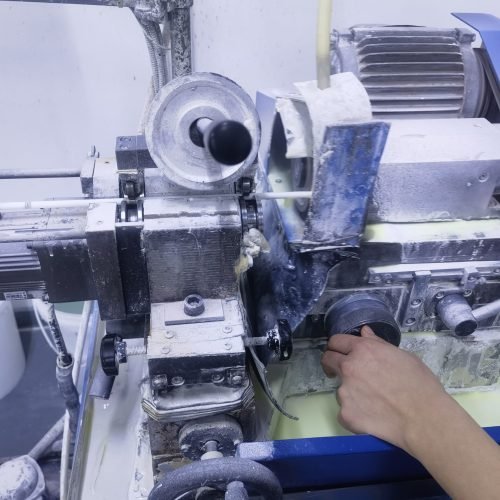

| Precision Machining | Can be ground/polished to tight tolerances and mirror-like finishes, ideal for shafts, plungers, rods. |

| Biocompatibility | Safe for medical devices, implants, and laboratory tools. |

| Aesthetic Appearance | White, smooth rods are clean and professional for visible or luxury product integration. |

Pump plungers & shafts – long life in abrasive or corrosive fluids

Medical devices – surgical tools, implants, dental posts (biocompatible, smooth surface)

Aerospace & automotive – lightweight but strong rods for precision components

Industrial machinery – guide rods, locating pins, spindles under vibration and shock

Luxury goods – watch components, decorative rods, design pieces due to clean white finish

| Property / Problem | Metal Rods | Plastic/Resin Rods | Glass Rods | Zirconia Rods |

|---|---|---|---|---|

| Wear Resistance | ⚠ Wears quickly | ❌ Scratches easily | ⚠ Brittle | ✅ Excellent, long life |

| Corrosion Resistance | ❌ Rusts | ⚠ Limited | ⚠ Poor | ✅ Outstanding in acids & alkalis |

| High Temp Resistance | ⚠ ~600 °C | ❌ ~250 °C | ⚠ Breaks under heat | ✅ ~1000 °C stable |

| Toughness | ✅ Strong but corrodes | ⚠ Weak | ❌ Very brittle | ✅ Highest among ceramics, impact-resistant |

| Electrical Insulation | ❌ Conductive | ⚠ Limited | ⚠ Partial | ✅ Excellent insulator |

| Lifetime & Cost | ⚠ Frequent replacement | ⚠ Short life | ⚠ Fragile | ✅ Long service life, lower maintenance |

Metal rods corrode, wear, or deform in chemical and high-temperature environments.

Plastic/resin rods soften, warp, or break under heat and load.

Glass rods are brittle and fail quickly under mechanical stress.

👉 If you’ve struggled with these failures, Zirconia Ceramic Rods are the solution: combining strength, toughness, and stability in demanding applications.

| Feature / Property | Alumina (Al₂O₃) | Zirconia (ZrO₂) | Silicon Nitride (Si₃N₄) | Silicon Carbide (SiC) |

|---|---|---|---|---|

| Max Temperature | ✅ ~1550 °C | ⚠ ~1000 °C | ✅ ~1100 °C | ✅ ~1400-1600 °C |

| Toughness | ⚠ Moderate | ✅ Very High | ✅ Good | ⚠ Moderate |

| Wear Resistance | ✅ Good | ✅ Very High | ✅ High | ✅ Extreme |

| Density | Medium (~3.9 g/cm³) | High (~6.0 g/cm³) | Light (~3.2 g/cm³) | Medium (~3.1 g/cm³) |

| Thermal Shock Resistance | ⚠ Moderate | ✅ Good | ✅ Excellent | ⚠ Moderate |

| Electrical Insulation | ✅ Excellent | ✅ Excellent | ✅ Excellent | ⚠ Semi-conductive |

| Best Fit Use | High heat, insulation | Impact/vibration, precision | Dynamic loads, light weight | Abrasive, corrosive, extreme wear |

Background:

A European pump OEM was using stainless steel rods in their plunger pumps for handling mildly acidic and abrasive fluids. The steel rods showed pitting corrosion and surface wear after only 3–4 months of operation. Frequent replacement caused downtime, maintenance costs, and lost productivity.

Challenge:

Severe corrosion from chemical exposure

Wear and abrasion shortened rod life

High maintenance costs and unexpected downtime

Solution with Zirconia Ceramic Rods:

The OEM switched to zirconia ceramic rods, precision-polished to ensure smooth sealing and long wear life. Zirconia’s toughness prevented cracking from pump vibration, while its inert nature resisted acid attack.

Results:

Service life extended from 3 months → 12+ months

Maintenance reduced by 70%

Improved pump efficiency due to low-friction rod surface

Total lifecycle cost significantly lower despite higher unit price

Background:

A U.S. medical device company produced minimally invasive surgical tools that required thin, high-strength rods to guide and stabilize components. Stainless steel rods had issues with ion release in contact with tissues and corrosion after repeated sterilization cycles.

Challenge:

Need for biocompatibility and safety in human use

Corrosion and degradation during autoclave sterilization

Desire for a smooth, low-friction surface finish

Solution with Zirconia Ceramic Rods:

The company adopted yttria-stabilized zirconia (Y-TZP) rods, polished to medical-grade surface finish. These rods are fully biocompatible, inert, and unaffected by repeated sterilization.

Results:

Zero corrosion after 500+ sterilization cycles

Stable, non-toxic performance in human tissue environment

Improved precision due to rod’s smooth surface finish

Regulatory approval achieved faster thanks to zirconia’s established biocompatibility track record

Powder → Forming → Sintering → CNC/Grinding → Inspection → Packaging → Delivery

Zirconia is much tougher, less brittle, and more impact-resistant, but alumina withstands higher temperatures.

Yes, zirconia is the best ceramic for impact and vibration resistance.

Yes, they are widely used in dental and medical implants.

Diameters from 1 mm to 100 mm, lengths up to 1000 mm, with tight tolerances. Customized as per your needs.

1 piece – ideal for prototyping.

20+ Years Ceramic Expertise – trusted by Apple, BYD, Huawei, and global leaders

Advanced Production – ISO9001 certified, SOP-controlled, and Apple-audited factory

Fast Lead Time – over 95% on-time delivery, higher than industry average

Custom Solutions – small MOQ (from 1 piece) to mass production, tailored to your design

Full Technical Support – our ceramic engineers help you choose the right grade and design

We will get back to you within 12 hours.